Strapping Machine Troubleshooting

The troubleshooting of baler is mainly to solve the common problems: sending Caton, not pulling tightly, not sticking firmly or cutting continuously. Usually I will first check whether there is a foreign body blockage and whether the strap path is smooth or not, and then adjust the tension or clean the blade and belt wheel.

Most of the time, it is not so much “repair” as “raising”. If it is a semi-automatic machine (one that requires manual assistance), you have to keep an eye on whether the operator has put on the strap correctly; if it is a fully automatic machine, the point is to check whether the sensor and program settings are stable. In fact, the vast majority of failures can be solved by cleaning with an air gun or replacing vulnerable parts such as springs and blades.

This video demonstrates how to troubleshoot common issues with a strapping machine’s strap dispenser:

Fix The Problem Of Belt Feeding And Unstable Tension

The two biggest problems on the packaging line are that the tape cannot be delivered, and the other is that the beaten bag is loose. When troubleshooting balers, the first step is always to touch the along the physical path of the tape.

Feeder Fault:

If the machine can’t swallow the belt, don’t rush to disassemble the machine first and see if there is any physical blockage or debris in the belt slot. A lot of times the problem is actually on the tape reel side-the tape is knotted around the reel. One more reminder, be sure to confirm that the size and type of packing belt match the machine specifications. When changing the new tape reel, level the leader and never feed the fixing tape into it, or it will definitely get stuck.

Insufficient Tension:

If the bag is too loose, nine times out of ten it is that the belt wheel or the tensioning claw is dirty, causing the belt to slip. Clean these parts thoroughly first. If it is still slipping after wiping, it is estimated that the tension spring is fatigued and worn, so replace it with a new one. If it is a numerical control model, don’t screw blindly, check the code, and fine-tune the tension setting on the electronic control panel.

Diagnosing Gluing, Cutters And Safety Hazards

The key to a qualified bag is to stick it firmly and cut it together. There is a problem in this area, usually because the parts are worn or the maintenance is not keeping up.

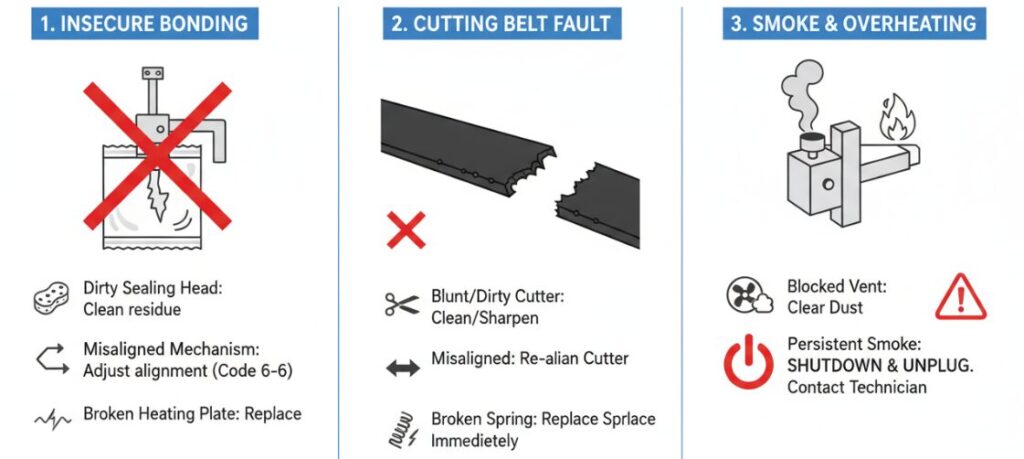

Insecure Bonding:

This usually means that the sealing head is dirty, or the mechanical mechanism is crooked. The technician should first clean up the hot head and the surrounding residue. If it still doesn’t stick after cleaning, check whether the heating plate is broken or adjust the bonding alignment (generally corresponding to code 6-6).

Fault Of Cutting Belt:

The incision of the strap is rough or not clean, either the cutter is blunt or dirty, or the compression spring is broken. The solution is simple: clean, re-align the cutting knife, or immediately replace the broken spring.

Smoke Problem:

If you smell or see smoke, first check if the vent is blocked by dust, causing the component to overheat. Clear the air immediately. If there is still smoke, don’t hesitate to shut down and cut off the power directly to prevent the motherboard and other expensive electrical components from burning out, and then contact our certified technician to have a look.

Resolve Power And Startup Failures

The machine doesn’t respond or doesn’t start? Don’t panic, the big problems are usually in the power supply and sensors.

Power And Safety Checks:

Let’s see if the power cord is plugged in tightly. The most easily overlooked thing on the scene is the emergency stop button. I have seen too many times that the machine does not move because the operator accidentally pressed it and locked it. Just make sure it is not pressed.

Battery And Sensor:

If you are using a hand-held electric packing tool, check whether the battery is fully charged and the card slot is in place. If it is that kind of full-automatic desktop computer, focus on checking the photo-eye (photo-eye sensors); This thing is most afraid of ash. Once it is covered by dust, the machine thinks that it is out of stock on the table and will naturally not move.

Routine Maintenance And Model-Specific Adjustment

At the end of the day, preventive maintenance is the most efficient troubleshooting. Establish a routine maintenance process that will keep your machine alive for years.

Daily Cleaning Procedures:

Take a high-pressure air gun every day to blow up the dust on the belt wheel, claw and cutter. Here I would like to give a serious warning: never take a screwdriver or metal tool to scratch, once these precision parts are scratched, the performance of the machine will be wasted by half.

The Correct Loading Skills:

When changing the tape reel, take a look at the direction of the tape. Generally speaking, the arrow should be back to the machine, so as to ensure smooth belt feeding.

Advanced Settings:

For a specific model like SQ-800, don’t flip through the operation manual based on your feeling. Familiarize yourself with those internal maintenance codes (from 6-1 to 6-8) so that you can fine-tune the machine’s performance with precision, rather than making wild guesses there.

Author: David Miller

“Hi, I’m a certified packaging machinery technician with over 17years of experience. I specialize in industrial maintenance and have spent thousands of hours servicing semi-automatic and automatic strappers. I hope to simplify strapping machine troubleshooting to help you minimize downtime and keep your production line running smoothly.”

Soonqian

Soonqian