Packaging Machine Maintenance

Regarding the maintenance of packaging machines, it is necessary to have preventive and predictive strategies, but also to combine the independent maintenance of operators. It is necessary to do a solid job of daily cleaning, lubrication, inspection and calibration, and to replace worn parts in time.

The purpose of this is straightforward: to minimize downtime and keep the equipment in use for several years, while ensuring product quality and operational efficiency. In practice, routine chores are usually handled by trained operators, while complex maintenance tasks are left to certified professional technicians.

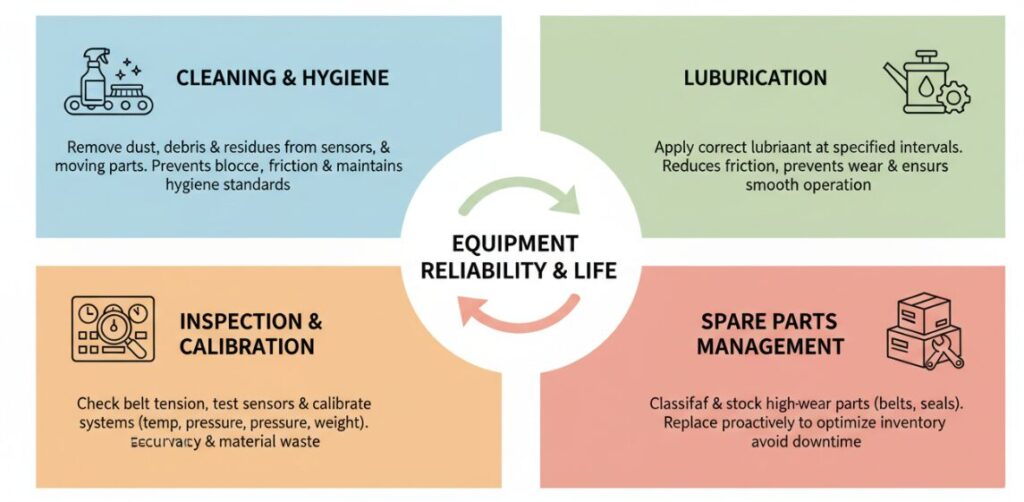

Key Maintenance Areas

If you want to ensure the reliability and life of the equipment, you must keep an eye on several core physical aspects of the machine.

Cleaning And Hygiene

The most basic aspect of maintenance is thorough cleaning. Over time, dust, debris and product residues are sure to accumulate on sensors, belts and moving parts. This one is most likely to be underestimated-if it is not cleaned up in time, the dust will not only block the sensor and cause the reading to be wrong, but also increase the friction of the moving parts. It cannot be overemphasized in the food and pharmaceutical packaging industry that the regular removal of these dirty things is not only to prevent failure, but also to maintain high hygiene standards.

Lubrication

The correct type of lubricant must be used strictly at the intervals specified by the manufacturer. This greatly reduces friction between gears, rollers and bearings. With less friction, overheating and premature wear can be prevented, and the machine can run smoothly and efficiently.

Inspection And Calibration

Routine inspection and calibration is the key to ensure packaging accuracy. The maintenance team must make it a habit to check the tension of the drive belt frequently for signs of damage. In addition, test sensors and calibration systems-especially those that monitor temperature, pressure and weight-ensure that the packaging process is error-free. Only calibration, in order to avoid material waste, but also to ensure compliance with packaging standards.

Spare Parts Management

Effective spare parts management must take the initiative. The key is to hoard the high-wear parts (such as belts and seals) and replace them before they break down completely. According to my experience, the parts according to high, medium and low wear rate classification management, can help you optimize the inventory level, to ensure that the critical moment on the shelf goods, not to catch blind.

Maintenance Strategy

A successful packaging machine maintenance plan is never “one size fits all”; it requires a mixture of several strategies, from daily routine inspections to data-based predictions.

Preventive Maintenance (PM)

Preventive maintenance is the cornerstone of equipment reliability. This strategy focuses on performing specific tasks according to the original equipment manufacturer (OEM) schedule. Usually done by skilled technicians, PM consists of a series of planned activities designed to nip the failure in the bud. Honestly implementing a strict PM schedule can help you avoid the chaos caused by most unexpected downtime.

Predictive Maintenance (PDM)

Predictive maintenance is a step further, the use of technical means to speak. This strategy uses data to monitor the health of the device in real time. By analyzing trends and performance indicators, operators can predict failures before they occur-such as a motor that is about to burn or an alignment problem. The biggest advantage of this data-driven approach is that you can intervene in repairs at the most appropriate time.

Autonomous Maintenance

Self-maintenance is actually the use of operators who deal with machines every day. The core of this strategy is to train operators to perform basic daily or weekly tasks, such as cleaning and visual inspection. With a standardized checklist, operators can be the first to spot minor anomalies, thus free up the time of certified technicians to handle more complex maintenance work.

Best Practices For Maintaining Success

A structured framework is needed to land the above strategy. Based on actual combat experience, adopting these practices will ensure that you get the maximum return on your maintenance investment:

- Schedule: According to the actual use of the machine, a detailed PM schedule. Tasks should be broken down by frequency-daily, weekly, monthly-to ensure that nothing is missed.

- Training Operators: Whether the machine is good or not depends to a large extent on people. Make sure that employees understand the basic principles of machine maintenance and understand their role in autonomous maintenance. A well-trained operator is the line of defense against downtime.

- Cooperation With Experts: Don’t be embarrassed to find manufacturers or professional service providers. Their expertise can sometimes be invaluable when solving complex technical problems or developing a PM plan for your specific equipment.

- Safety Is A Priority: Maintenance and safety are not home-to-home. Integrating safety checks into all maintenance processes not only protects personnel, but also ensures the safe operation of the machine.

- Stock Up On Spare Parts: To stop is to burn money. Keep critical spare parts readily available, which can significantly reduce repair time. There is exactly that part on the shelf that can turn a shutdown crisis that could last a few days into a few-minute episode.

About the Author: David Miller

With over 14 years of experience as a Certified Industrial Technician, I specialize in optimizing packaging line efficiency. I wrote this guide to help you master packaging machine maintenance, sharing the practical preventive and predictive strategies I use daily to minimize downtime and extend equipment life.

Soonqian

Soonqian