How To Make Blister Packing Machine

The core of a blister packaging machine is to build a thermoforming system. You need racks, heating units, molds and vacuum pumps to set the plastic, and then you integrate the filling and sealing stations-usually aluminum foil as the cover material-to create protective packaging in a continuous process.

The whole process requires high precision of heating, vacuum and sealing. This is not only to put the parts together, to deal with the cooperation of PVC forming and aluminum foil sealing, as well as the subsequent cutting and punching, is the key to the technical work.

The following is a specific technical disassembly on how to manufacture such equipment:

Core Components And Structural Assemblies

To understand how to build this machine, we must first disassemble its physical architecture. Don’t think of it as a single black box, it is actually a series of precision series of stations.

Rack And Structure Construction

The basis of any blister packaging machine is a rigid frame. You need to build a solid, horizontal metal frame that can carry all the components that follow. This rack has two key functions:

Stability: The heating element, mold and vacuum motor are not light, and the frame must be able to withstand it.

Shock absorption: In the vacuum blister and sealing stage, machine vibration is the culprit leading to deviation (misalignment). A heavy metal frame can ensure that the machine does not shift during operation, which is essential to ensure the precise alignment of the blister hole position and the sealing aluminum foil.

Integrated Heating System

The molding process begins with heating. The task of this system is to soften the PVC plastic sheet (soften) and make it malleable. Usually we will install infrared heaters with precision thermostats to build this station.

Target Temperature: The system is typically stable at around 300 °F (150°C).

Uniformity: The heating must be uniform. If the heating is uneven, weak points will appear when the mold is formed, or the edges are not sharp enough, and the blister to be made is very poor.

Die Station

The core technology of “how to make blister packaging machine” is actually in the mold station. The flat plastic sheet is turned into a 3D shape here.

Mold processing: You need to customize the mold, generally made of aluminum, because of its good thermal conductivity. The surface of the mold must be smooth to ensure smooth flow of plastic.

Vacuum integration: the mold has to be drilled full of tiny pores, connected to the vacuum pump. Once the heated plastic film is covered on the mold, the vacuum pump is activated to instantly “suck” the hot plastic into the mold cavity. This strong adsorption creates those well-defined blisters.

Filling And Sealing Mechanism

After the blister is formed, it enters the packaging link:

Product loading: The molded blister moves to the filling area and puts the product into the cavity.

Cover Laminating: The feeding mechanism is covered with a cover, usually aluminum foil.

Heat sealing: The aluminum foil is pressed against the PVC base using a heated sealing plate. This step is to activate the adhesive layer on the aluminum foil by heat and pressure, so that it and the blister are permanently bonded to form an airtight seal.

Cutting And Punching Unit

A die cutter is usually installed at the end of the production line. Its job is simple but crucial:

Slitting: cutting a continuous sealed strip of material into individual packages.

Dashed lines: Dashed lines at specific locations on the packaging to ensure that the end user can easily tear the product.

Key Operating Principles

Just know which parts are only half successful, and understand the operation principle so as not to be blind in debugging.

Thermoforming And Vacuum Dynamics

The main principle of manufacturing blister packaging machines is thermoforming. The thermoplastic sheet is heated to a rubber-elastic state, and then-the point is made-a vacuum negative pressure.

I have seen many low-end machines in the field, and the problem often lies in the vacuum. The difference between high-quality machines is that the vacuum must be strong enough to attach it to every detail of the mold after the plastic is heated and before it is cooled and shaped.

Temperature Control Accuracy

Temperature control is definitely the biggest variable.

Too hot: If the heater power is too high, the PVC will degrade, scorch or become too thin, causing the blister to rupture.

Too cold: The plastic does not stretch, the shape collapses, and the details are blurred.

When manufacturing this machine, reliable sensors and controllers must be installed to keep the temperature within 300 °F (150°C), and the smaller the fluctuation, the better.

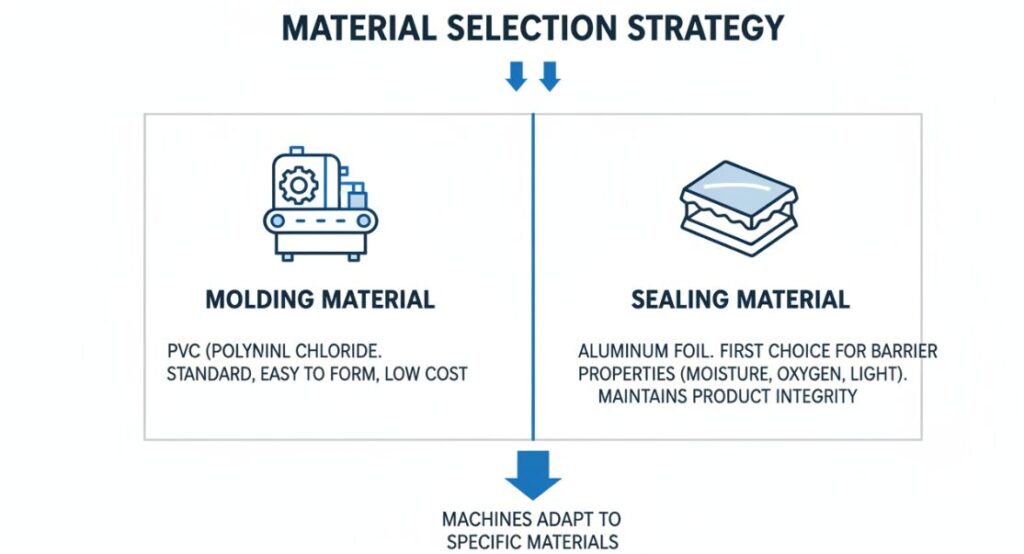

Material Selection Strategy

Machines have to be picky about food and have to adapt to specific materials.

Molding material: PVC (polyvinyl chloride) is standard, easy to form and low cost.

Sealing material: aluminum foil is the first choice, because of its good barrier properties (moisture, oxygen, light), can keep the integrity of the product inside.

Production Scale: DIY Vs. Industrial Grade

How to build this machine depends to a large extent on how big you want to build it.

For DIY Or Small Scale Production

If it is only for proofing or small batch production, the design can be completely simplified. DIY is usually a simple vacuum blister machine. At this level, you don’t need to engage in too complex automation, focusing on mold making and vacuum forming principles. It is also common to manually place sheets and manually operate pressure sealing machines, which can save a lot of engineering complexity.

For Industrial Scale

To engage in industrial-grade blister packaging machines is a completely different engineering level. You need a fully automated subsystem to implement:

Continuous feeding of coils.

Step synchronously (Indexing, let the film advance at a precise pitch).

High speed sealing and cutting.

Industrial machines are about speed, repeatability and minimum downtime, which requires advanced PLC (programmable logic controller) and pneumatic systems.

Author: James Thorne

“As a senior packaging engineer with a focus on thermoforming dynamics, I specialize in the structural design of automated machinery. I help engineers and manufacturers understand the precision required in heating, vacuum, and sealing systems to build efficient blister packing solutions.”

Soonqian

Soonqian