How Packing Machine Works

The packaging machine uses conveyor belts to transport products, sensors to count/weigh, and systems such as forming, filling, and sealing to realize automatic sorting and packaging of products, thereby making films into packaging bags or filling prefabricated containers. All processes are controlled by a central PLC to ensure consistent and efficient packaging with minimal manual intervention. The general process includes: product/film feeding, packaging molding, precision filling and finished product sealing/cutting, usually with the option of printing or inflation.

Step 1: Material Conveying And Feeding

The entire process begins with the raw material entering the system. According to the physical characteristics of the material (particles, liquid or solid), the feeding method is very important:

- Conveyor belts: mainly responsible for the smooth handling of products from the processing area.

- Vibratory feeder: Ensure the continuity of material flow through controlled vibration frequency. The fine adjustment of vibration frequency is very important. If it is adjusted properly, it can effectively prevent the material from accumulating or blocking, which is the premise to ensure the efficiency of the whole line.

- Pick-and-Place Arms: This scheme is usually used for fragile goods or materials with strict requirements on the direction of placement.

Step 2: Film And Bag Making

In the “form-fill-seal” system, the machine processes the material and simultaneously processes the package material. Large rolls of flat film are unwound and conveyed under constant tension.

When the film moves to the former (commonly known as “elephant nose mouth” or Lapel Former), the flat film will be forced into a cylindrical shape and wrapped around the periphery of the filling tube. Subsequently, longitudinal seal rolls (Longitudinal Sealing Bar) will press the edges of the film together to form a continuous longitudinal weld seam. Here is a technical detail: if the film tension is not well controlled, the bag will deviate, which is the most troublesome problem for many novice engineers.

Step 3: Accurate Metering And Blanking

Accuracy is the soul of automated packaging machines. The machine will integrate different metering mechanisms according to the physical properties of the product:

- Multi-head Scales: First choice for snacks and irregularly shaped solids.

- Screw metering machine: specifically for ultra-fine powder, can prevent dust flying, but also to ensure accurate volume.

- Liquid filling pump: using a pump or piston for volumetric dosing.

Once the measurement is completed, the material will fall directly into the semi-formed packaging bag through the forming cylinder.

Step 4: Core Components: The “Brain” And “Eyes” Of The Machine

The reason why the packaging machine can achieve high-speed seamless connection depends on the deep communication between the mechanical structure and the electronic control system.

- Central PLC (Programmable Logic Controller): This is the brain of the machine. It manages the timeline of all actions-ensuring that the moment the film moves, the material falls exactly and the sealing pressure lasts exactly the same.

- Advanced Sensors: They are the eyes of the machine. The sensor is responsible for monitoring:

- Material in place: prevent waste of packaging materials caused by empty bag sealing.

- Weight and position: confirm the filling quantity twice.

- Color mark tracking: This is very critical in actual production. The sensor must accurately capture the color mark on the film and ensure that the cutter falls exactly in the middle of the pattern, otherwise your brand Logo will be cut off.

Step 5: Final Stage: Sealing, Cutting And Discharge

After the product is loaded, the machine must ensure a sealed environment to ensure food safety and shelf life.

- Sealing: The cross sealing knife presses the film under the action of pressure and heat. It is a “two birds with one stone” action: the top seal of the current bag and the bottom seal of the next bag are completed at the same time.

- Optional function: In this link, we usually add nitrogen to discharge oxygen to extend the shelf life, or spray code (print batch number and expiration date).

- Cut and Discharge: The finished product is cut from the continuous film by a sharp cutter. The packaged product is then sent to the rear end for packing or palletizing via a discharge conveyor.

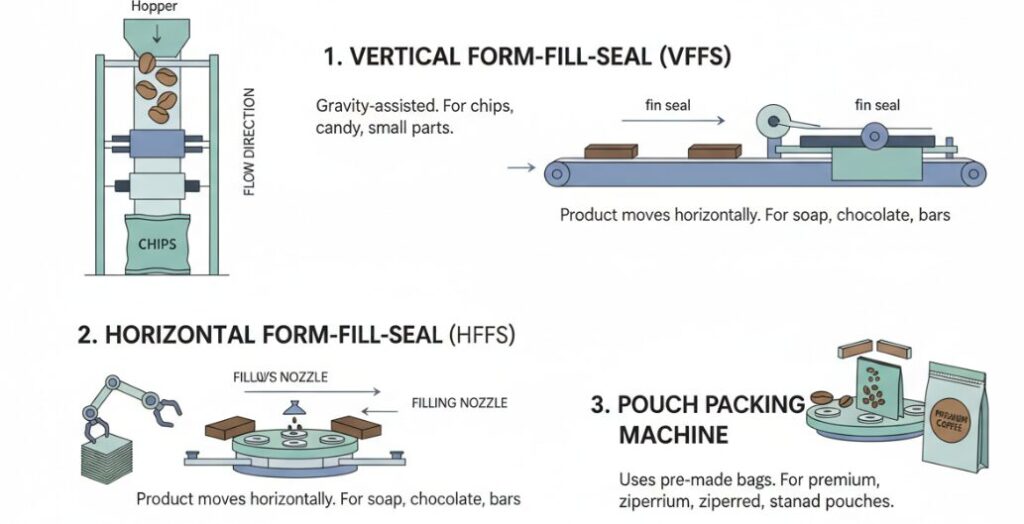

Common Packaging Machine Structure Type

Not all packaging needs can be addressed with the architecture. Flow direction and container type determine the physical form of the machine.

- Vertical packaging machine (VFFS): The whole process is vertically downward. Using gravity-assisted blanking, this is the standard configuration in the potato chips, candy and hardware parts industries.

- Horizontal packaging machine (HFFS): The material moves horizontally, and the film wraps the product like rice dumplings (usually called “pillow packaging”), which is very suitable for soap, chocolate bars and other regular-shaped solids.

- Pouch packing machine: This machine does not make bags, but directly processes ready-made bags. The mechanical arm completes bag taking, bag opening, filling and sealing. If you are looking for a high-end sense (such as a zippered stand-up bag), the bag style is usually a better choice.

To sum up: the packaging machine is essentially a high degree of coordination of mechanical action through heat, pressure and precision metering. The speed and consistency of this complexity is completely unmatched by traditional manual packaging. A well-tuned automatic packaging system is not only the end of the production line, but also the first line of defense for product quality.

Author: David Miller

“I’m a packaging systems engineer with over 10 years of experience in industrial automation. Throughout my career, I have designed and optimized hundreds of VFFS and HFFS production lines. I am passionate about deconstructing complex mechanical workflows into easy-to-understand insights, helping manufacturers leverage automation to achieve maximum efficiency and precision in their packaging operations.”

Soonqian

Soonqian