Search the whole station

Designed for fragile or unstable palletized goods, the pallet load is locked through multi-layer horizontal strapping, which effectively prevents interlayer dislocation and collapse during transportation, realizes automatic packaging efficiency of up to 60 pallets per hour, and supports batch ordering.

60 torr/hour

Strapping efficiency

3000 Newton

Maximum pulling force

9-19mm

Applicable bandwidth

The Siemens PLC control system combined with photoelectric induction can automatically detect the load height with an accuracy of 1mm, accurately locate the key strapping points, and adapt to pallets of different heights without manual adjustment.

Using high-frequency friction welding to replace the traditional metal buckle connection, the tensile strength of the joint reaches more than 85% of the parent tape, which not only eliminates the cost of metal buckles, but also avoids the risk of rust polluting the goods.

Equipped with a variable frequency adjustable tension of up to 3000 Newton, it provides constant tightening force for different goods such as heavy building materials or light beverage bottles to ensure that the goods are not loose or displaced during long-distance transportation.

The unique floating head design can automatically fit uneven cargo surfaces, and with a high-speed belt feeding mechanism, the single-channel strapping cycle is compressed to less than 15 seconds, significantly increasing the throughput of the production line.

The core guide rail and cutter are made of vacuum heat-treated die steel with a hardness of HRC60. Under high-strength continuous operation environment, the replacement cycle of wearing parts is extended to more than 200000 strapping.

The system supports standard signal interface, can be seamlessly connected to the existing roller or chain conveyor line, supports multi-level emergency stop linkage and fault self-diagnosis, and reduces the waiting time of the whole line caused by equipment shutdown.

| Parameter Items | Specifications |

| drive system | Servo motor + frequency converter control |

| Applicable pallet sizes | L1200 x W1200 mm (maximum) |

| Bundling speed | 15 seconds/pass (approximately 60 trays/hour) |

| Bundling tensile strength | 200 – 3000 N (infinitely adjustable) |

| Applicable packing straps | PP or PET plastic steel belt |

| Packing tape width | 9, 12, 15, 19 mm |

| Packing strap paper core | 406 mm (Standard ID) |

| Adhesion method | Friction welding |

| Power specifications | 380V, 50/60Hz, 3-phase |

| Total weight | Approximately 1250 kg |

| control system | PLC (Programmable Logic Controller) + Touchscreen HMI |

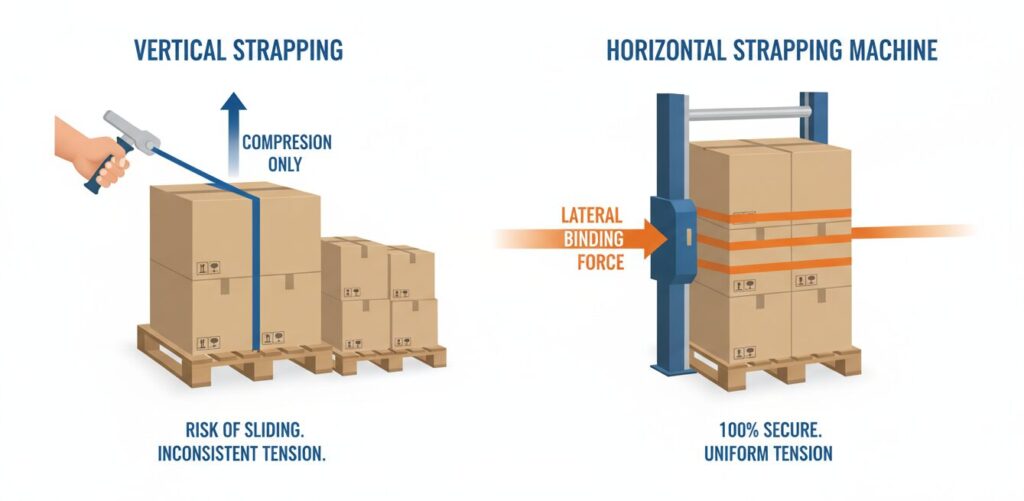

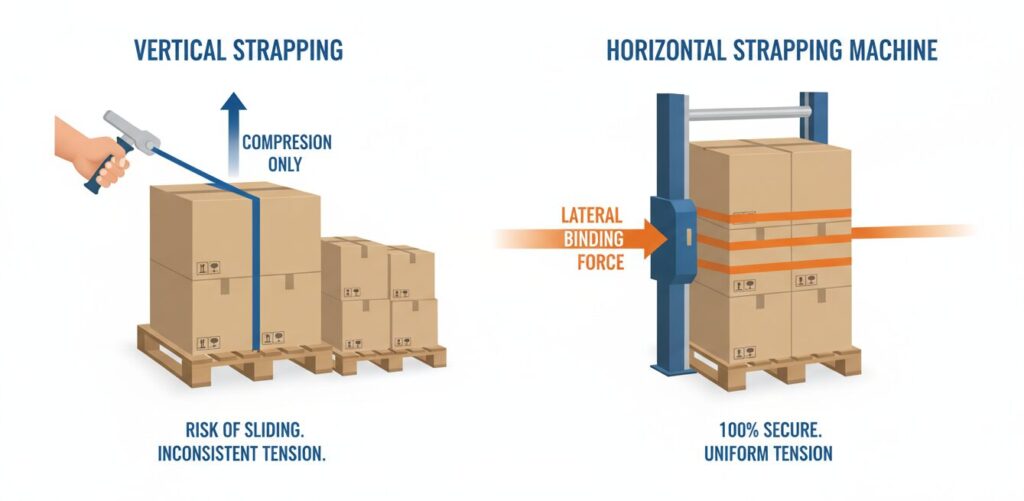

Compared with traditional manual tools or vertical balers, the core advantage of this fully automatic horizontal baler is the lateral binding force on stacked goods. Vertical packing can only press the goods on the pallet, while horizontal packing can bind multiple layers of goods into a whole like a “belt”, preventing the physical structure from sliding off the layers. In addition, fully automated operations have increased the standardization of packaging to 100 per cent, completely eliminating the tightness caused by human manipulation.

Scene description: For PET bottled beverages, cans or glass bottle stacking. This kind of cargo single-layer contact area is small, easy to be scattered in the forklift transport. The horizontal baler can ensure that each layer of bottle body is tightly combined to prevent the whole tray from dumping.

Scene description: Suitable for packing of aerated concrete blocks, red bricks or tiles. These products are heavy and have rough surfaces. The high-tension PET belt strapping function of the machine can replace expensive steel belts and ensure the absolute safety of heavy loads.

Scenario description: For bagged granular materials (e. g. fertilizer, resin pellets). Bagged goods are prone to deformation and “big belly” phenomenon after stacking. Horizontal strapping can effectively tighten the bagged shape and improve the stability of storage stacking.

Scenario description: For a distribution center with a daily throughput of more than 500 pallets. The high-speed automation feature of the equipment can be directly connected to the automated three-dimensional library (AS/RS) to meet the stringent requirements of the unmanned workshop for packaging rhythm.

The palletized pallets are placed in the center of the baler through the conveyor line or forklift, and the photoelectric sensor will automatically detect whether the goods are in place and lock the conveying roller.

Select the preset mode on the HMI touch screen (such as “top two channels + bottom two channels”), set the pulling force value, and press the “automatic operation” button to start the program.

The head assembly automatically lifts and scans the height of the goods, and completes the tape feeding, tightening, tape cutting and hot-melt welding actions in sequence according to the set position, without manual intervention in the whole process.

After all the strapping passes are completed, the rack is automatically reset to the origin, the signal light of the conveying line turns green, and the packaged pallet is conveyed to the next 1 process or waiting for picking up.

certificate

Welcome to our Frequently Asked Questions page. We have compiled answers to common questions you may have, hoping to provide you with clear and quick solutions. If you cannot find the information you need here, please feel free to contact our customer support team.

Designed for fragile or unstable palletized goods, the pallet load is locked through multi-layer horizontal strapping, which effectively prevents interlayer dislocation and collapse during transportation, realizes automatic packaging efficiency of up to 60 pallets per hour, and supports batch ordering.

Strapping efficiency

60 torr/hour

Maximum pulling force

3000 Newton

Applicable bandwidth

9-19mm

The Siemens PLC control system combined with photoelectric induction can automatically detect the load height with an accuracy of 1mm, accurately locate the key strapping points, and adapt to pallets of different heights without manual adjustment.

Using high-frequency friction welding to replace the traditional metal buckle connection, the tensile strength of the joint reaches more than 85% of the parent tape, which not only eliminates the cost of metal buckles, but also avoids the risk of rust polluting the goods.

Equipped with a variable frequency adjustable tension of up to 3000 Newton, it provides constant tightening force for different goods such as heavy building materials or light beverage bottles to ensure that the goods are not loose or displaced during long-distance transportation.

The unique floating head design can automatically fit uneven cargo surfaces, and with a high-speed belt feeding mechanism, the single-channel strapping cycle is compressed to less than 15 seconds, significantly increasing the throughput of the production line.

The core guide rail and cutter are made of vacuum heat-treated die steel with a hardness of HRC60. Under high-strength continuous operation environment, the replacement cycle of wearing parts is extended to more than 200000 strapping.

The system supports standard signal interface, can be seamlessly connected to the existing roller or chain conveyor line, supports multi-level emergency stop linkage and fault self-diagnosis, and reduces the waiting time of the whole line caused by equipment shutdown.

| Parameter Items | Specifications |

| drive system | Servo motor + frequency converter control |

| Applicable pallet sizes | L1200 x W1200 mm (maximum) |

| Bundling speed | 15 seconds/pass (approximately 60 trays/hour) |

| Bundling tensile strength | 200 – 3000 N (infinitely adjustable) |

| Applicable packing straps | PP or PET plastic steel belt |

| Packing tape width | 9, 12, 15, 19 mm |

| Packing strap paper core | 406 mm (Standard ID) |

| Adhesion method | Friction welding |

| Power specifications | 380V, 50/60Hz, 3-phase |

| Total weight | Approximately 1250 kg |

| control system | PLC (Programmable Logic Controller) + Touchscreen HMI |

Scene description: For PET bottled beverages, cans or glass bottle stacking. This kind of cargo single-layer contact area is small, easy to be scattered in the forklift transport. The horizontal baler can ensure that each layer of bottle body is tightly combined to prevent the whole tray from dumping.

Scene description: Suitable for packing of aerated concrete blocks, red bricks or tiles. These products are heavy and have rough surfaces. The high-tension PET belt strapping function of the machine can replace expensive steel belts and ensure the absolute safety of heavy loads.

Scenario description: For bagged granular materials (e. g. fertilizer, resin pellets). Bagged goods are prone to deformation and “big belly” phenomenon after stacking. Horizontal strapping can effectively tighten the bagged shape and improve the stability of storage stacking.

Scenario description: For a distribution center with a daily throughput of more than 500 pallets. The high-speed automation feature of the equipment can be directly connected to the automated three-dimensional library (AS/RS) to meet the stringent requirements of the unmanned workshop for packaging rhythm.

The palletized pallets are placed in the center of the baler through the conveyor line or forklift, and the photoelectric sensor will automatically detect whether the goods are in place and lock the conveying roller.

Select the preset mode on the HMI touch screen (such as “top two channels + bottom two channels”), set the pulling force value, and press the “automatic operation” button to start the program.

The head assembly automatically lifts and scans the height of the goods, and completes the tape feeding, tightening, tape cutting and hot-melt welding actions in sequence according to the set position, without manual intervention in the whole process.

After all the strapping passes are completed, the rack is automatically reset to the origin, the signal light of the conveying line turns green, and the packaged pallet is conveyed to the next 1 process or waiting for picking up.