Flow Wrap Machine Working Principle

The working principle of the “Flow Wrap Machine” is a process that allows packaging films and products to achieve precise “integration” in high-speed operation.

Through continuous roll film, a film tube is formed around the conveyor belt product, which is first sealed vertically, then sealed horizontally and cut off. Finally, individual packages like “pillows” come out one by one. The reason why this process can become the standard of snack, baking, or candy industry is its “continuity”.

This video provides a brief overview of how a flow wrap packaging machine operates:

The following is a detailed dismantling based on actual engineering logic:

Step 1: Film Feeding And Tube Forming

The whole process starts with a roll of film. After the machine is started, the web is drawn under constant tension towards the former. The core principle here is actually geometric transformation: the former folds the planar two-dimensional packaging film into a three-dimensional tube shape through precise angle design.

This forming machine is the “skeleton” of the whole machine. If the design is not good, or the tension control of the film is unstable, the film will wrinkle at the forming stage, which will directly lead to the subsequent seal scrap.

Step 2: Synchronized Product Infeed

At this stage, accuracy is everything. The product is entered by a conveyor belt (manual or automatic). The core of the working principle lies in the “beat”, and the conveyor belt must be completely synchronized with the formed film tube.

Each product must be slid into the membrane tube at a precise point in time. If there is a deviation in synchronization, the product will be stuck in the sealing knife position, causing downtime. This synchronicity is the key to prevent product stacking and ensure that the sealing point falls on the gap.

Vertical Packing

Vertical sealing servo, heat sealing servo

cold sealing servo, cutter servo

DKXL-650

Precision weighing or multi-head scales ensure consistent bag weight, with quality sensors enhancing packaging accuracy.

WP20

Automatically complete the processes of bag making, measuring, filling, sealing, bag cutting, etc., greatly improving the packaging speed.

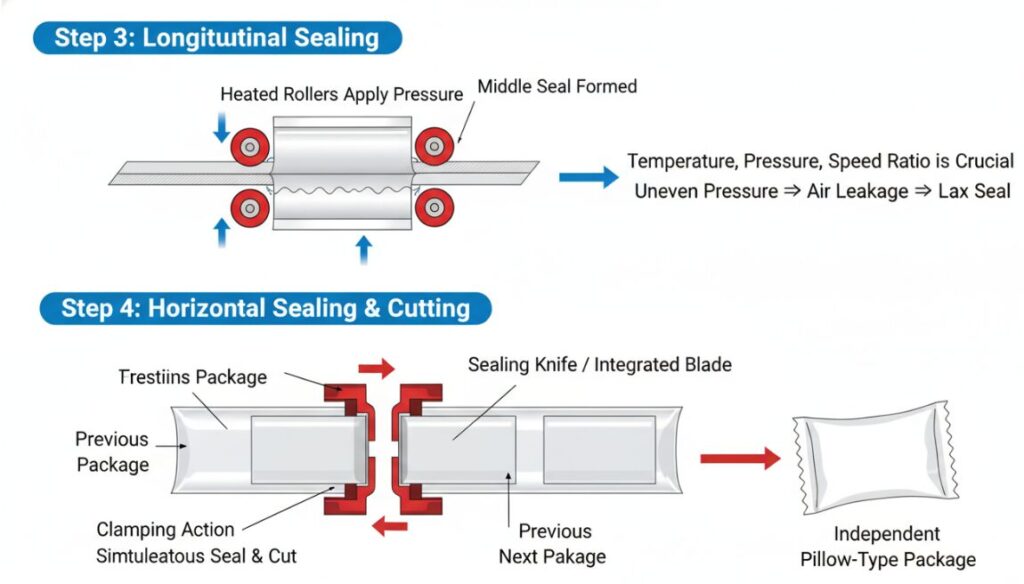

Step 3: Longitudinal Sealing

When the product is drilled into the membrane tube, the two edges of the membrane meet underneath. The machine applies pressure to the edge through heated rollers or sealing strips to form a longitudinal seal, which is what we often call “middle seal”.

Here, the ratio of temperature, pressure, and speed must be just right. According to my observation of on-site debugging, many problems of lax sealing are often not due to insufficient temperature, but due to air leakage caused by uneven pressure distribution.

Step 4: Horizontal Sealing And Cutting

This is the most violent part of the whole machine. The continuous film tube wrapped with the product moves forward to reach the sealing and cutting mechanism.

- Sealing: The sealing knife rotates or reciprocates, and clamps hard at the gap between the two products to instantly complete the tail seal of the previous package and the head seal of the next package.

- Cutting: At the moment of sealing, the blade integrated in the sealing knife acts to cut off the continuous film tube.

- This set of “consecutive moves” directly turns the long-length film tube into an independent pillow-type package.

Step 5: Finished Output

Finally, the packaged products are sent out through the export conveyor belt. At this time, it already has the function of moistureproof and protection, and can directly enter the packing link.

Core Components Of Flow Wrap Machine

To really understand this principle, you have to look at the hardware behind it:

- Forming device: This is a precision processing part, which determines the “selling phase” of the packaging.

- Knife sealing mechanism: They are the core of heat transfer. The temperature must be constant, not only to ensure that the seal is firm, but also can not burn through the film.

- Servo motors and sensors: This is the soul of modern packaging machines. Now better machines use servo technology to capture the “Eye Mark” on the film through high-precision sensors. The PLC system fine-tunes the motor speed in real time according to the signal. To be honest, without the millisecond compensation of the servo system, it is almost impossible to cut accurately at high output.

The Principle Of “On-The-Fly” Efficiency

The biggest technical advantage of the pillow packaging machine is “On-the-fly”, that is, continuous production. Unlike the stop-and-go rhythm of vertical packaging machines, pillow machines complete all actions in motion.

Through the high synchronization of film speed, feed speed, and knife speed, the machine can achieve a silky “flow”. This efficiency is why it can wrap hundreds of loaves of bread or chocolates a minute. For factories pursuing output, this continuous movement mode is the ultimate solution to ensure food freshness and packaging consistency.

Author: Alex Thompson

“I am a mechanical engineer specializing in automated packaging systems. With over a decade of hands-on experience in the field, I have dedicated my career to optimizing HFFS (Horizontal Form Fill Seal) workflows. In this article, I break down the flow wrap machine working principle based on my technical expertise in film tension control, synchronized sealing jaws, and high-speed motion logic. “

Soonqian

Soonqian