Search the whole station

Cold Seal Packaging Machine adopts pressure induction sealing technology, which can realize rapid packaging within 0.1 seconds without heating. It is specially designed to provide packaging guarantee without hurting products for chocolate, medical devices and heat-sensitive materials. Its production efficiency is improved by more than 30% compared with traditional heat sealing, and it undertakes wholesale business.

Sealing speed: 100-250 packs/min

Compressed air consumption: ≥ 0.6 Mpa

Coil width range: 50-450mm

| Parameter name | Specifications | Remark |

| Model Name | CS-450 Series | Industrial-grade cold sealing packaging machine |

| Maximum packaging speed | 250 bags/min | Depends on the length of the packaging |

| Bag length range | 60 mm – 600 mm | Touchscreen digital adjustment |

| Bag width range | 30 mm – 200 mm | Adjustable molder |

| Thin film thickness requirements | 20 μm – 80 μm | Cold sealant coating required |

| Total power | 3.5 kW | Far lower than heat sealing machines of the same specifications (7-9kW) |

| Rated voltage | 220V/380V 50Hz | Supports global voltage customization |

| Machine net weight | Approximately 850 kg | Heavy-duty carbon steel or stainless steel frame |

| Equipment dimensions (L W H) | 4000x950x1600 mm | Standard industrial floor space |

Energy efficiency ratio advantage: this cold sealing packaging machine saves high-power electric heating system, and the operating power consumption of the whole machine is only 40%-50% of that of the same level of heat sealing equipment. for large factories pursuing low-carbon production, a single equipment can save about us $3,000-5,000 in electricity charges per year.

Instantaneous encapsulation capability: With pressure sensitive adhesive (PSA) characteristics, sealing is done at the moment of contact. Compared with the time required for heat sealing to wait for heat to penetrate the film, the processing speed of this equipment is increased by 1.5 times when encapsulating heat-sensitive pharmaceutical reagents.

For chocolate, ice cream and fat-containing candies, the problem of softening of the product edge, taste change or packaging adhesion caused by the residual heat of the heat seal is solved.

For some heat-sensitive sterile medical paper bags or ultra-thin films, the risk of heat shrinkage of materials, wrinkles at the sealing and damage to the sterile barrier during the heat sealing process is solved.

the pain points that the heating tube of the heat sealer is easy to burn out and the carbon deposit on the head needs to be cleaned frequently are solved. The mechanical structure of the equipment is simple and the maintenance period is prolonged by about 200.

solve the problem of high workshop temperature and excessive air conditioning load due to the large amount of heat emitted by multiple heat sealers, and significantly improve the comfort of second-line operators.

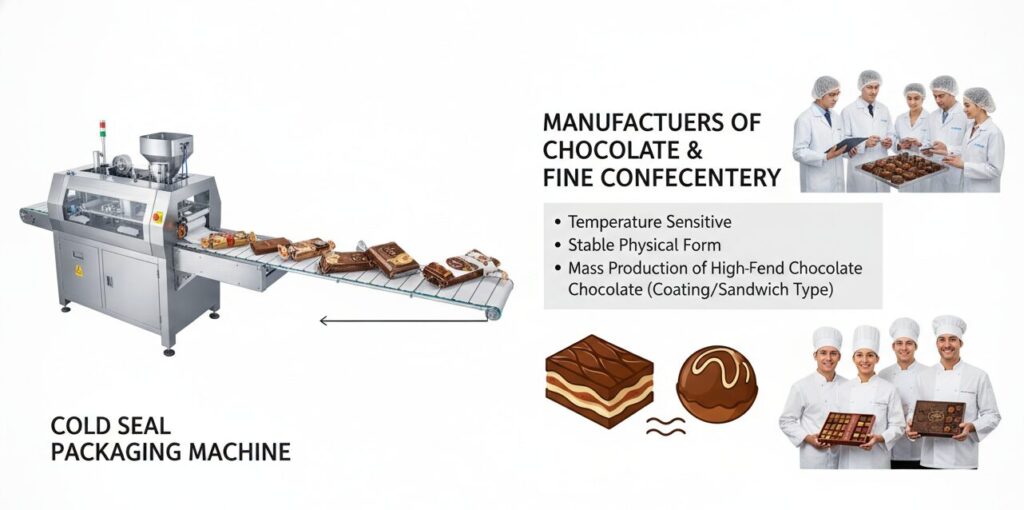

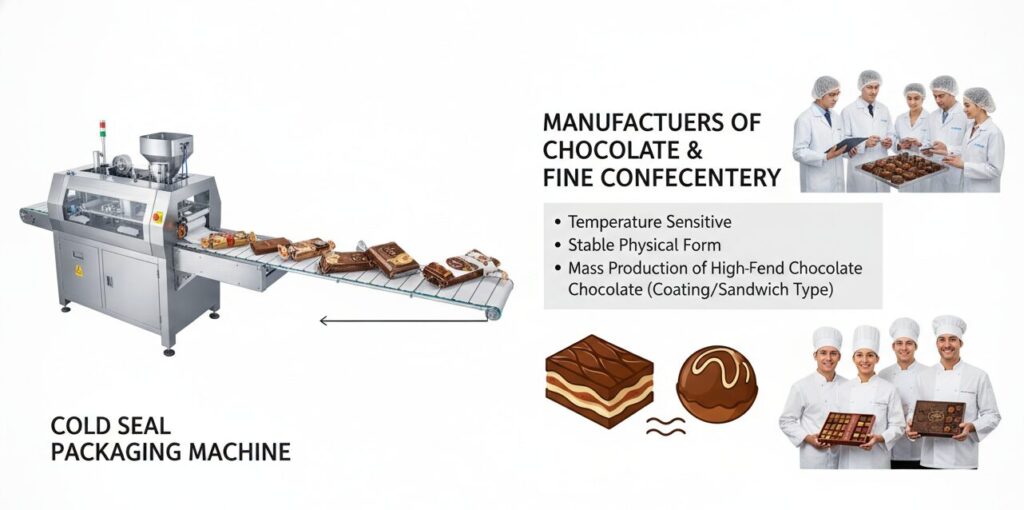

These products are extremely sensitive to temperature. The cold seal packaging machine can ensure that the product maintains a stable physical form during the packaging process, and is especially suitable for the mass production of high-end chocolate of coating or sandwich type.

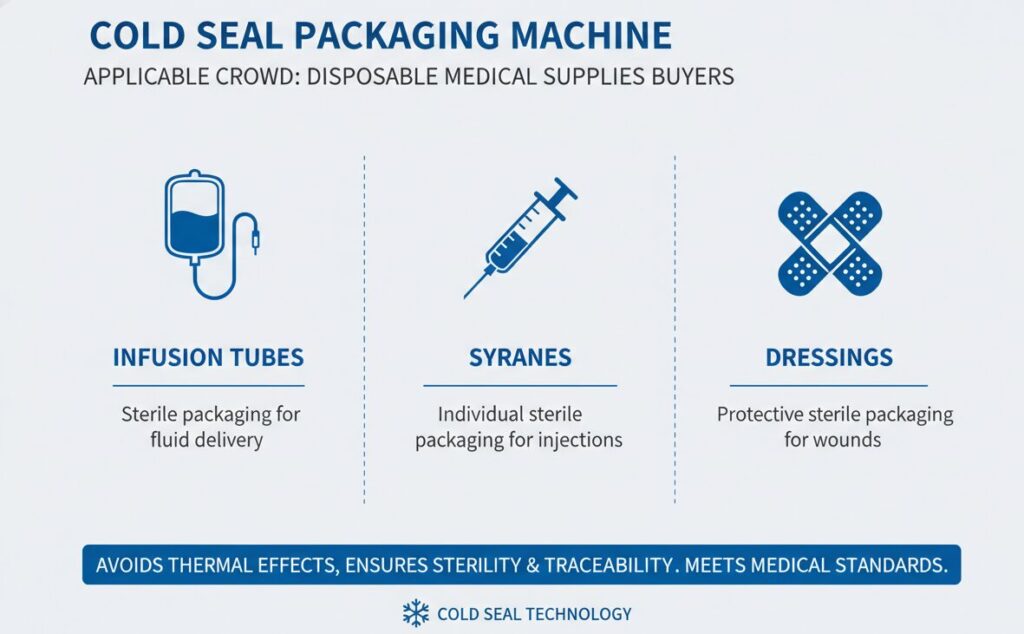

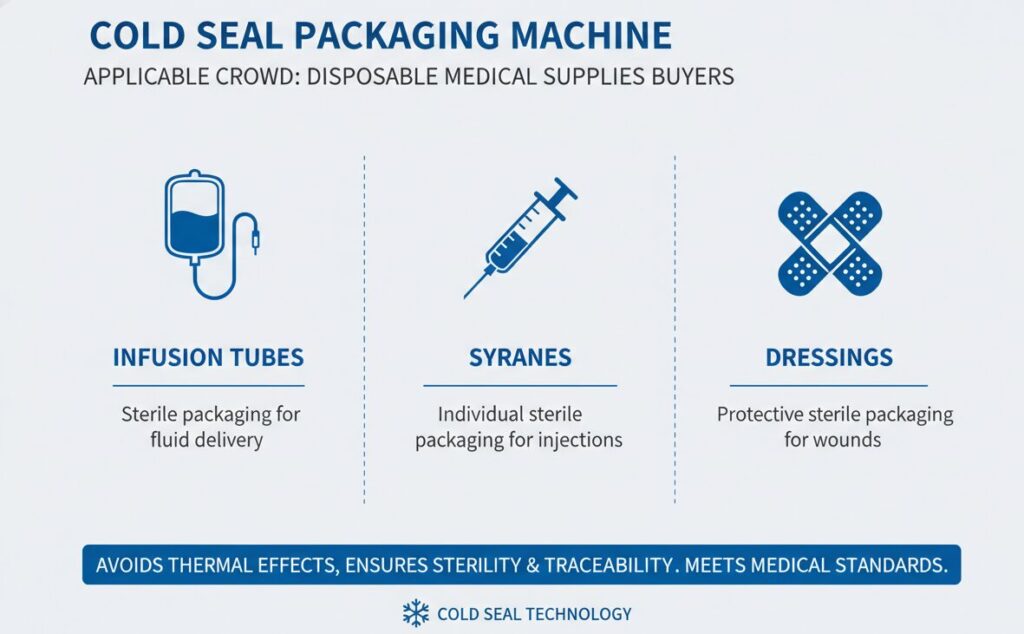

used for infusion tubes, syringes, dressings and other sterile packaging. Cold seal technology avoids thermal effects on the performance of medical devices and meets the medical industry’s strict standards for packaging integrity and traceability.

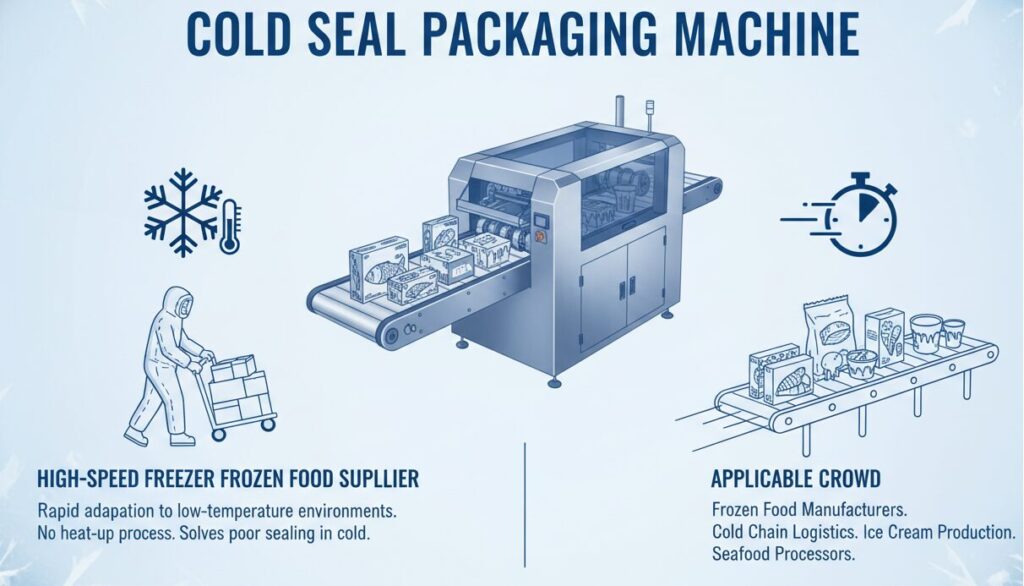

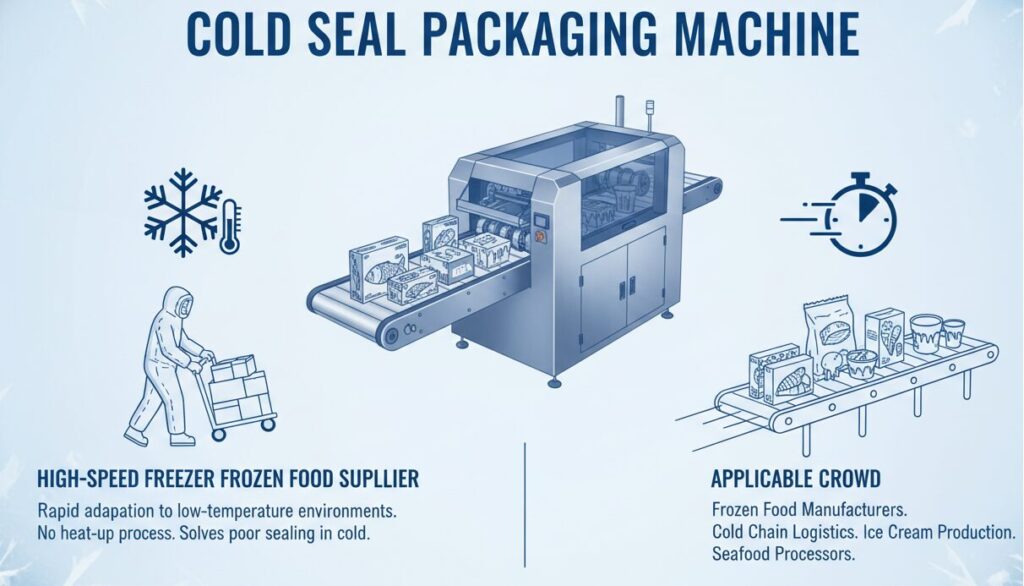

In the cold chain environment, the equipment does not need to heat up the process, can quickly adapt to the operation of the low-temperature workshop, and solve the problem of poor sealing or slow start-up of ordinary packaging machines in cold environments.

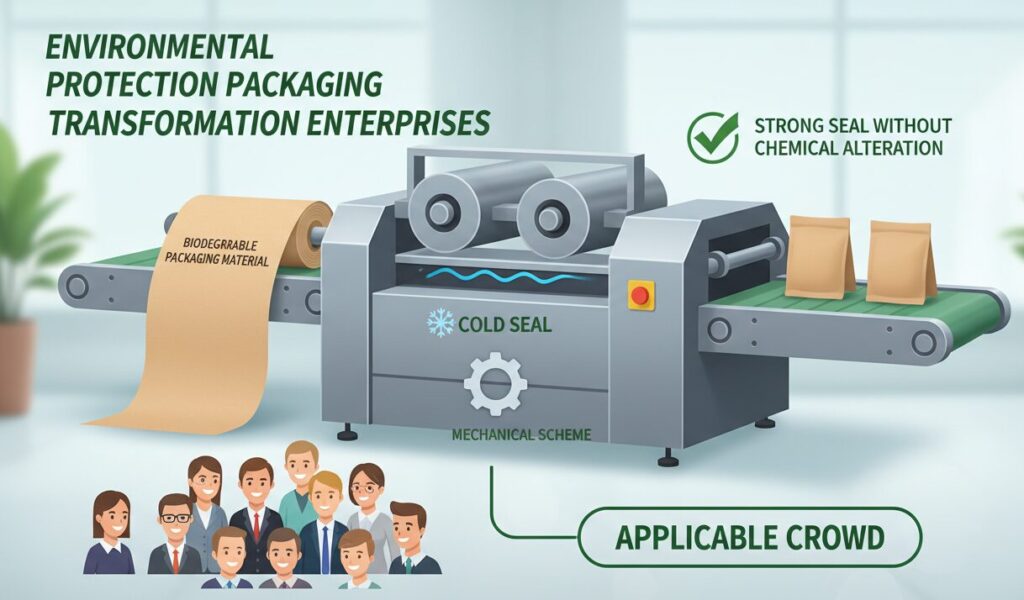

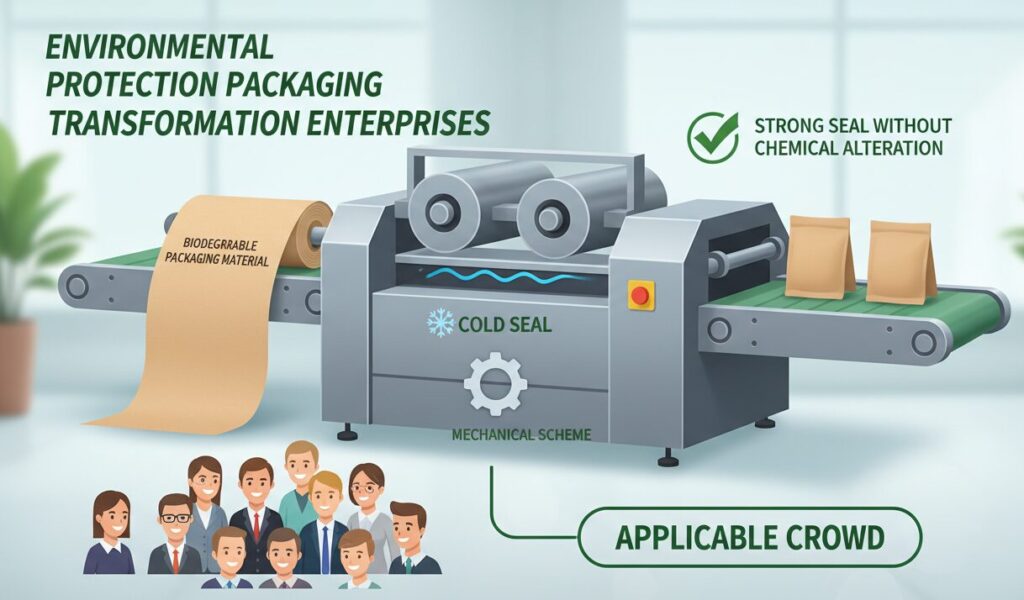

for brands that use biodegradable materials such as coated paper, cold sealing machine provides a 1 mechanical scheme that can realize strong sealing without changing the chemical characteristics of materials.

35 years mastering light: Where proven expertise meets future-forward illumination technologies.

A: Yes. The cold sealing machine must be used with the film or paper whose surface is pre-coated with pressure-sensitive glue (Cold Seal Adhesive), and the ordinary plastic film cannot be bonded only by mechanical pressure.

A: As long as the matching cold sealing glue and sufficient pressure are selected, the peel strength can reach 3-5N/15mm, which fully meets the sealing and transportation requirements of chocolate, candy and disposable medical devices.

A: Cold sealant has the best performance at 15°C-25°C. If the workshop temperature is too low and the glue activity decreases, it may be necessary to fine-tune and increase the pressing force; if it is too high, it is necessary to prevent the coil from self-sticking during storage.

A: Lower maintenance costs. Since there are no heating elements, slip rings and high temperature sensors, the most important maintenance work is only regular replacement of the pressure roller sealing ring and cleaning of the pressure wheel, and the life of the accessories is longer.

A: Yes. By changing the shaper of different specifications (Forming Box) and adjusting the length of the cut bag on the touch screen, the specification switch from small candy to large medical dressing can be completed within 30 minutes.

A: Usually because of improper tension control. Please check the parameter setting of the unwinding tension magnetic powder brake, and ensure that the parallelism between the film feed roller and the former is within the tolerance of 0.1mm.

Cold Seal Packaging Machine adopts pressure induction sealing technology, which can realize rapid packaging within 0.1 seconds without heating. It is specially designed to provide packaging guarantee without hurting products for chocolate, medical devices and heat-sensitive materials. Its production efficiency is improved by more than 30% compared with traditional heat sealing, and it undertakes wholesale business.

Sealing speed: 100-250 packs/min

Compressed air consumption: ≥ 0.6 Mpa

Coil width range: 50-450mm

| Parameter name | Specifications | Remark |

| Model Name | CS-450 Series | Industrial-grade cold sealing packaging machine |

| Maximum packaging speed | 250 bags/min | Depends on the length of the packaging |

| Bag length range | 60 mm – 600 mm | Touchscreen digital adjustment |

| Bag width range | 30 mm – 200 mm | Adjustable molder |

| Thin film thickness requirements | 20 μm – 80 μm | Cold sealant coating required |

| Total power | 3.5 kW | Far lower than heat sealing machines of the same specifications (7-9kW) |

| Rated voltage | 220V/380V 50Hz | Supports global voltage customization |

| Machine net weight | Approximately 850 kg | Heavy-duty carbon steel or stainless steel frame |

| Equipment dimensions (L W H) | 4000x950x1600 mm | Standard industrial floor space |

Energy efficiency ratio advantage: this cold sealing packaging machine saves high-power electric heating system, and the operating power consumption of the whole machine is only 40%-50% of that of the same level of heat sealing equipment. for large factories pursuing low-carbon production, a single equipment can save about us $3,000-5,000 in electricity charges per year.

Instantaneous encapsulation capability: With pressure sensitive adhesive (PSA) characteristics, sealing is done at the moment of contact. Compared with the time required for heat sealing to wait for heat to penetrate the film, the processing speed of this equipment is increased by 1.5 times when encapsulating heat-sensitive pharmaceutical reagents.

For chocolate, ice cream and fat-containing candies, the problem of softening of the product edge, taste change or packaging adhesion caused by the residual heat of the heat seal is solved.

For some heat-sensitive sterile medical paper bags or ultra-thin films, the risk of heat shrinkage of materials, wrinkles at the sealing and damage to the sterile barrier during the heat sealing process is solved.

the pain points that the heating tube of the heat sealer is easy to burn out and the carbon deposit on the head needs to be cleaned frequently are solved. The mechanical structure of the equipment is simple and the maintenance period is prolonged by about 200.

solve the problem of high workshop temperature and excessive air conditioning load due to the large amount of heat emitted by multiple heat sealers, and significantly improve the comfort of second-line operators.

These products are extremely sensitive to temperature. The cold seal packaging machine can ensure that the product maintains a stable physical form during the packaging process, and is especially suitable for the mass production of high-end chocolate of coating or sandwich type.

used for infusion tubes, syringes, dressings and other sterile packaging. Cold seal technology avoids thermal effects on the performance of medical devices and meets the medical industry’s strict standards for packaging integrity and traceability.

In the cold chain environment, the equipment does not need to heat up the process, can quickly adapt to the operation of the low-temperature workshop, and solve the problem of poor sealing or slow start-up of ordinary packaging machines in cold environments.

for brands that use biodegradable materials such as coated paper, cold sealing machine provides a 1 mechanical scheme that can realize strong sealing without changing the chemical characteristics of materials.

35 years mastering light: Where proven expertise meets future-forward illumination technologies.

A: Yes. The cold sealing machine must be used with the film or paper whose surface is pre-coated with pressure-sensitive glue (Cold Seal Adhesive), and the ordinary plastic film cannot be bonded only by mechanical pressure.

A: As long as the matching cold sealing glue and sufficient pressure are selected, the peel strength can reach 3-5N/15mm, which fully meets the sealing and transportation requirements of chocolate, candy and disposable medical devices.

A: Cold sealant has the best performance at 15°C-25°C. If the workshop temperature is too low and the glue activity decreases, it may be necessary to fine-tune and increase the pressing force; if it is too high, it is necessary to prevent the coil from self-sticking during storage.

A: Lower maintenance costs. Since there are no heating elements, slip rings and high temperature sensors, the most important maintenance work is only regular replacement of the pressure roller sealing ring and cleaning of the pressure wheel, and the life of the accessories is longer.

A: Yes. By changing the shaper of different specifications (Forming Box) and adjusting the length of the cut bag on the touch screen, the specification switch from small candy to large medical dressing can be completed within 30 minutes.

A: Usually because of improper tension control. Please check the parameter setting of the unwinding tension magnetic powder brake, and ensure that the parallelism between the film feed roller and the former is within the tolerance of 0.1mm.