Search the whole station

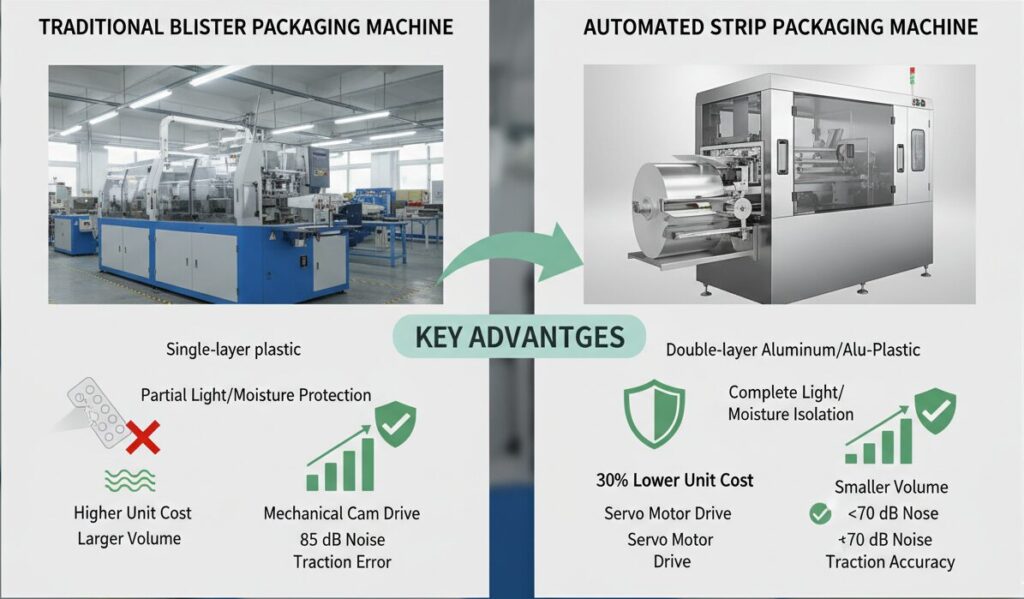

This automatic strip packaging machine is specially designed for tablets and capsules. It meets the standard of quality management of pharmaceutical production and provides high-speed sealed packaging of up to 2500 tablets per minute. The equipment adopts two-way heat sealing technology to ensure that the drugs have excellent moisture-proof and light-proof performance, significantly improve the production efficiency of small and medium-sized pharmaceutical factories and foundry enterprises, and support bulk procurement.

2,500 grains per minute

Production speed:

260mm

Maximum width:

4kw

Overall power:

Using PID intelligent temperature control technology, the surface temperature fluctuation of the heat seal roller is controlled within plus or minus 1 degree, which ensures that the air tightness of the aluminum foil sealing reaches 99.9%, and effectively prevents the medicine from being affected with moisture and deterioration.

Equipped with vertical vibration feeding channel, the feeding accuracy rate exceeds 99.5, effectively solves the problem of tablet stuck and empty package, and adapts to various dosage forms such as flat tablets, special-shaped tablets and capsules.

All parts in contact with drugs are made of 316 stainless steel, and the body shell is made of 304 stainless steel, which fully meets the requirements of drug production quality management standards, corrosion resistance and easy to clean.

Integrated PLC programmable logic controller and touch screen man-machine interface, support one-key adjustment of cut-off speed and travel distance, operators only need 1 hour of training to be skilled.

The optimized cutter design controls the width of the packaging edge waste within 1mm. Compared with traditional models, it can save about 15% of the cost of aluminum foil or composite film materials for enterprises every year.

The drawer-type mold installation structure is adopted, and it only takes 20 minutes to replace the molds of different specifications of drugs, which greatly shortens the downtime change time for multi-variety and small batch production.

| Parameter Items | DSL-260 High-Speed Model | DSL-320 Wideband |

| punching frequency | 40-80 times/minute | 40-70 times/minute |

| Production capacity | 800-2500 particles/minute | 1200-3500 particles/minute |

| Maximum packaging width | 260 mm | 320 mm |

| Applicable packaging material thickness | 0.05-0.10 mm | 0.05-0.10 mm |

| Heat sealing heating power | 2.0 kW | 3.2 kilowatts |

| Main motor power | 0.75 kilowatts | 1.5 kilowatts |

| Power specifications | 380 volts / 50 Hz | 380 volts / 50 Hz |

| Compressed air pressure | 0.4-0.6 MPa | 0.4-0.6 MPa |

| Total weight | 900 kg | 1200 kg |

| External dimensions | 1500×850×1700 mm | 1800×1100×2100 mm |

It is suitable for pharmaceutical factories that need to change production varieties frequently and are sensitive to the initial return on investment of equipment to meet their flexible production needs of multi-specifications and small batches.

For the foundry to undertake a variety of dosage form packaging orders, the high compatibility of the equipment can handle round, oval tablets and all kinds of capsules, improve the ability to receive orders.

It is suitable for enterprises that produce vitamin C effervescent tablets or fish oil capsules that are easy to oxidize and absorb moisture. The double aluminum sealing structure can extend the shelf life of the product to the greatest extent.

The widened conveying channel specially designed for large-size tablets solves the problem of blanking blockage caused by large diameter and weight of veterinary tablets, and is suitable for the packaging of veterinary anthelmintic drugs.

Turn on the power supply and air source, set the heat sealing temperature on the touch screen to 150 degrees, preheat for 15 minutes until the temperature is stable, and ensure that the sealing roller reaches the working heat.

Install the aluminum foil coil to the unwind reel, pass the upper and lower layers of film through the guide roller, heat seal roller and cutter assembly respectively according to the schematic diagram of film penetration, and align the edges manually.

Pour the tablets into the stainless steel hopper, turn on the vibration feeder, run the equipment in low speed mode, and observe whether the tablets fall into the film interlayer accurately.

After confirming the package effect is correct, switch to automatic mode. After the end of production, need to use copper brush to clean the surface residue after cooling the heat seal roller, to prevent carbon deposition affect the next use.

certificate

Welcome to our Frequently Asked Questions page. We have compiled answers to common questions you may have, hoping to provide you with clear and quick solutions. If you cannot find the information you need here, please feel free to contact our customer support team.

Manufacturer of vertical bagging machine and bag sealer machine, ideal for sealing and packaging of various bag types.

Manufacturer of automatic tea bag packing machine and snack packaging machine for precise food product packaging.

Manufacturer of TD200A air bag and pillow packing machine. Reliable packing machine for industrial cushion packaging.

Manufacturer of RL140 horizontal biscuit packaging machine. Efficient pack machine for biscuits and small food products.

loading…

已经是到最后一篇内容了!

This automatic strip packaging machine is specially designed for tablets and capsules. It meets the standard of quality management of pharmaceutical production and provides high-speed sealed packaging of up to 2500 tablets per minute. The equipment adopts two-way heat sealing technology to ensure that the drugs have excellent moisture-proof and light-proof performance, significantly improve the production efficiency of small and medium-sized pharmaceutical factories and foundry enterprises, and support bulk procurement.

Production speed:

2,500 grains per minute

Maximum width:

260mm

Overall power:

4kw

Using PID intelligent temperature control technology, the surface temperature fluctuation of the heat seal roller is controlled within plus or minus 1 degree, which ensures that the air tightness of the aluminum foil sealing reaches 99.9%, and effectively prevents the medicine from being affected with moisture and deterioration.

Equipped with vertical vibration feeding channel, the feeding accuracy rate exceeds 99.5, effectively solves the problem of tablet stuck and empty package, and adapts to various dosage forms such as flat tablets, special-shaped tablets and capsules.

All parts in contact with drugs are made of 316 stainless steel, and the body shell is made of 304 stainless steel, which fully meets the requirements of drug production quality management standards, corrosion resistance and easy to clean.

Integrated PLC programmable logic controller and touch screen man-machine interface, support one-key adjustment of cut-off speed and travel distance, operators only need 1 hour of training to be skilled.

The optimized cutter design controls the width of the packaging edge waste within 1mm. Compared with traditional models, it can save about 15% of the cost of aluminum foil or composite film materials for enterprises every year.

The drawer-type mold installation structure is adopted, and it only takes 20 minutes to replace the molds of different specifications of drugs, which greatly shortens the downtime change time for multi-variety and small batch production.

| Parameter Items | DSL-260 High-Speed Model | DSL-320 Wideband |

| punching frequency | 40-80 times/minute | 40-70 times/minute |

| Production capacity | 800-2500 particles/minute | 1200-3500 particles/minute |

| Maximum packaging width | 260 mm | 320 mm |

| Applicable packaging material thickness | 0.05-0.10 mm | 0.05-0.10 mm |

| Heat sealing heating power | 2.0 kW | 3.2 kilowatts |

| Main motor power | 0.75 kilowatts | 1.5 kilowatts |

| Power specifications | 380 volts / 50 Hz | 380 volts / 50 Hz |

| Compressed air pressure | 0.4-0.6 MPa | 0.4-0.6 MPa |

| Total weight | 900 kg | 1200 kg |

| External dimensions | 1500×850×1700 mm | 1800×1100×2100 mm |

It is suitable for pharmaceutical factories that need to change production varieties frequently and are sensitive to the initial return on investment of equipment to meet their flexible production needs of multi-specifications and small batches.

For the foundry to undertake a variety of dosage form packaging orders, the high compatibility of the equipment can handle round, oval tablets and all kinds of capsules, improve the ability to receive orders.

It is suitable for enterprises that produce vitamin C effervescent tablets or fish oil capsules that are easy to oxidize and absorb moisture. The double aluminum sealing structure can extend the shelf life of the product to the greatest extent.

The widened conveying channel specially designed for large-size tablets solves the problem of blanking blockage caused by large diameter and weight of veterinary tablets, and is suitable for the packaging of veterinary anthelmintic drugs.

Turn on the power supply and air source, set the heat sealing temperature on the touch screen to 150 degrees, preheat for 15 minutes until the temperature is stable, and ensure that the sealing roller reaches the working heat.

Install the aluminum foil coil to the unwind reel, pass the upper and lower layers of film through the guide roller, heat seal roller and cutter assembly respectively according to the schematic diagram of film penetration, and align the edges manually.

Pour the tablets into the stainless steel hopper, turn on the vibration feeder, run the equipment in low speed mode, and observe whether the tablets fall into the film interlayer accurately.

After confirming the package effect is correct, switch to automatic mode. After the end of production, need to use copper brush to clean the surface residue after cooling the heat seal roller, to prevent carbon deposition affect the next use.