Search the whole station

This Candy Flow Wrapping Machine is specially designed for high-frequency production. With three-axis servo drive and sealing and cutting accuracy of ± 0.5mm, it achieves a stable output of up to 800 grains per minute, significantly improves the packaging automation rate and supports bulk purchases.

Packing speed:

800 pieces/minute

Film width:

within 120mm

Sealing and cutting precision:

± 0.5mm

the use of independent servo motor drive film feeding, feeding and cross-sealing, eliminating the cumulative error generated by mechanical chain transmission, so that packaging film loss reduced by 15%, extending the mechanical life of more than 5 years.

built-in high-precision sensor, real-time capture of packaging film color code displacement, automatic compensation of stretching error, to ensure that the pattern cutting position is always centered, the qualified rate of finished products reached 99.8.

all contact material parts and body shell are made of SUS304 stainless steel, in line with HACCP and FDA food safety standards, rust and corrosion resistance, support fast flushing.

the sealing system is equipped with an independent PID temperature controller, and the temperature difference fluctuation is controlled at 1 ℃. It can be adapted to BOPP, polyester film and various composite packaging materials to avoid film burning or air leakage due to uneven temperature.

the intelligent induction system automatically stops the film when detecting the material vacancy, and prevents the knife holder from cutting when the material position is offset, effectively reducing the frequency of downtime maintenance and protecting the cutter.

the optimized physical feeding path reduces the friction and damage of candy in the conveying process, and with the adjustable bag length system, the time to replace products of different specifications is shortened to 10 minutes.

| Technical Specification | Standard Value |

| Product Model | CFW-Series High Speed |

| Thin film material | BOPP, PVC, OPP/CPP, PT/PE, KSA, AL/PE |

| Packaging speed (Capacity) | 200 – 800 bags/min (depending on material size) |

| Bag Length | 40mm – 120mm |

| Bag Width | 20mm – 80mm |

| Product Height | Max. 35mm |

| Film roll diameter. | Max. 320mm |

| Machine Weight | Approximately 750kg |

| Power Supply Specifications | 220V/380V, 50/60Hz, 3.8kW |

| Machine dimensions | (L)3900mm × (W)920mm × (H)1500mm |

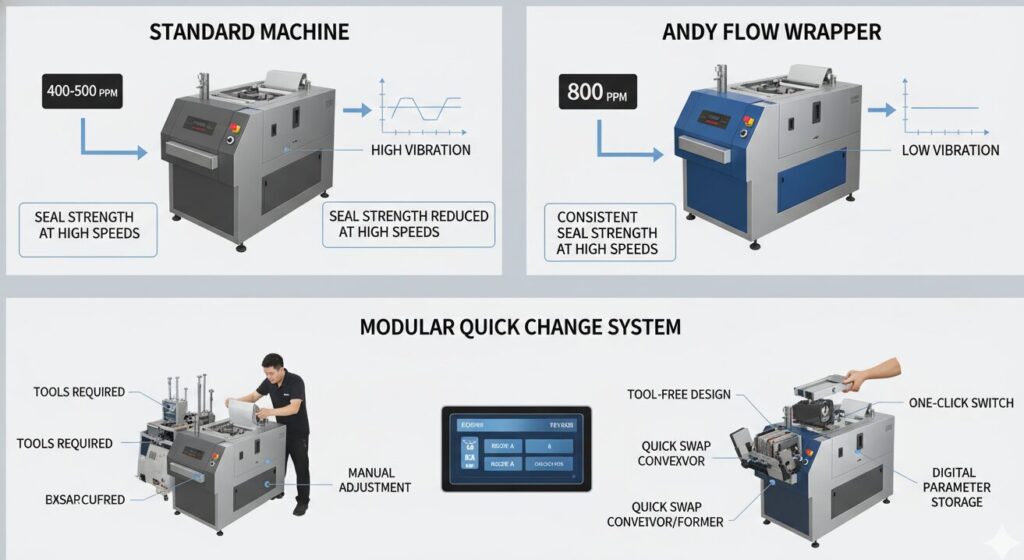

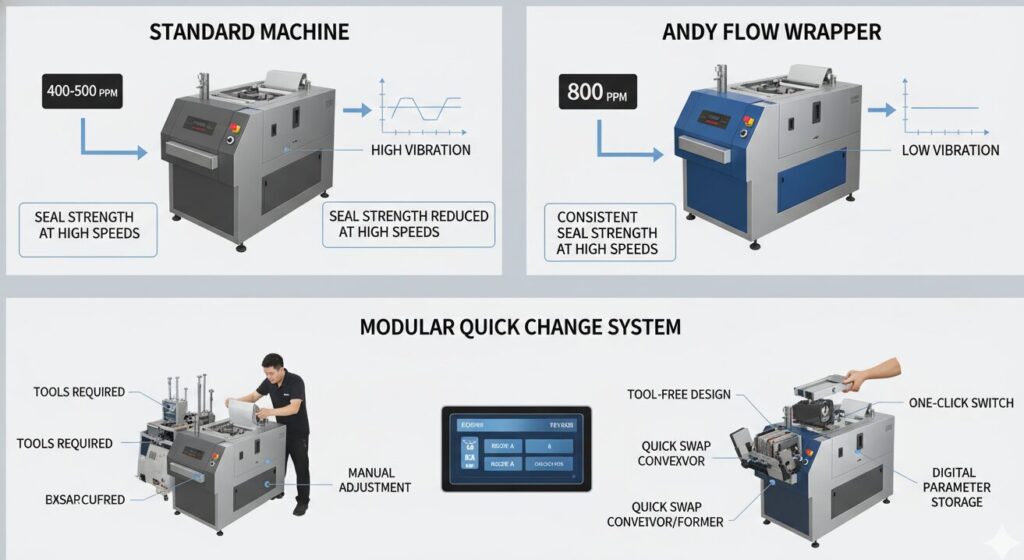

Fast production and stability: compared with the common frequency of 400-500 pieces/minute in the same industry, this equipment can maintain extremely low vibration value under high-speed operation of 800 pieces/minute through the cross-sealing tool holder optimized by dynamic balance, so as to ensure that the sealing strength is not reduced under long-term continuous operation and solve the efficiency bottleneck in large-scale production.

Modular quick change system: For multi-variety candy production line, this machine adopts tool-free quick disassembly design, and the former and conveyor belt can be switched in a short time. Combined with the parameter storage function of the digital touch screen, the “one-click switching” of different sizes of candy packaging is realized, which greatly improves the multi-tasking ability.

in view of the moisture absorption characteristics of hard candy and chocolate, a pressurized horizontal sealing mechanism is adopted to solve the problem of packaging air leakage caused by insufficient sealing pressure of traditional machines at high speed.

for printing packaging materials, the system has automatic calibration function, which solves the problem of incomplete pattern cutting or wrong brand logo position caused by uneven tension of packaging materials.

in view of the unstable pace of manual feeding, the system has its own material standby mode, which solves the waste of packaging materials and the labor cost of sorting empty bags caused by “running empty bags with nothing” in the traditional packaging machine.

suitable for the pursuit of the ultimate production capacity and unit energy consumption ratio of food groups, its high-speed output capacity can perfectly match the multi-channel candy molding line, to achieve full automation and seamless docking.

specially optimized for temperature-sensitive products, the heat conduction control of the sealing area is accurate, and the quality control problem of chocolate melting or surface damage during the packaging process is solved.

to meet their needs for rapid replacement of packaging specifications, one device can cover the packaging tasks of mints, chewing gum, lollipops and other small-size desserts.

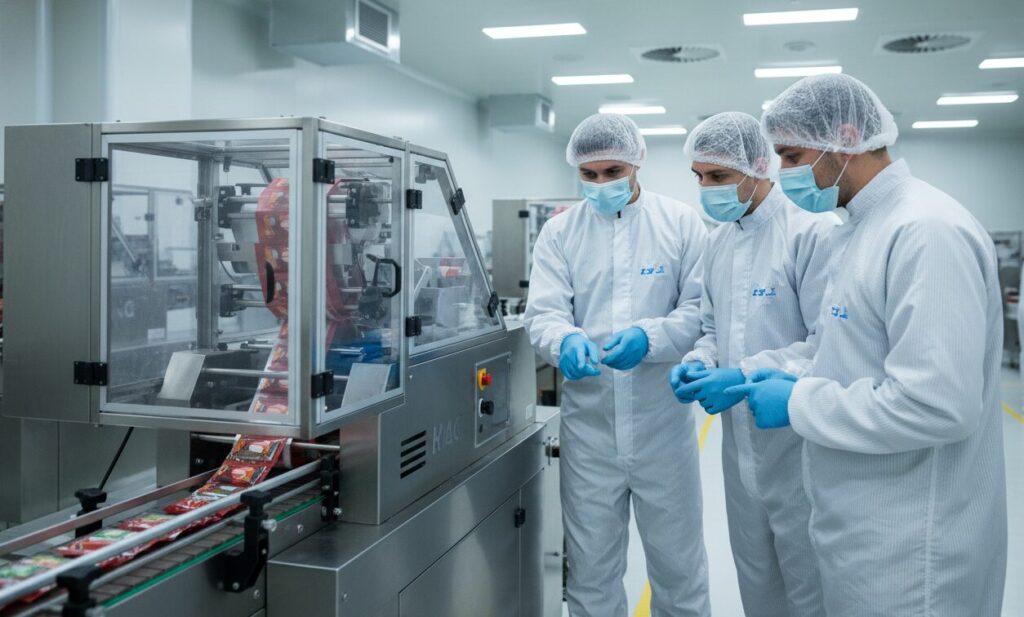

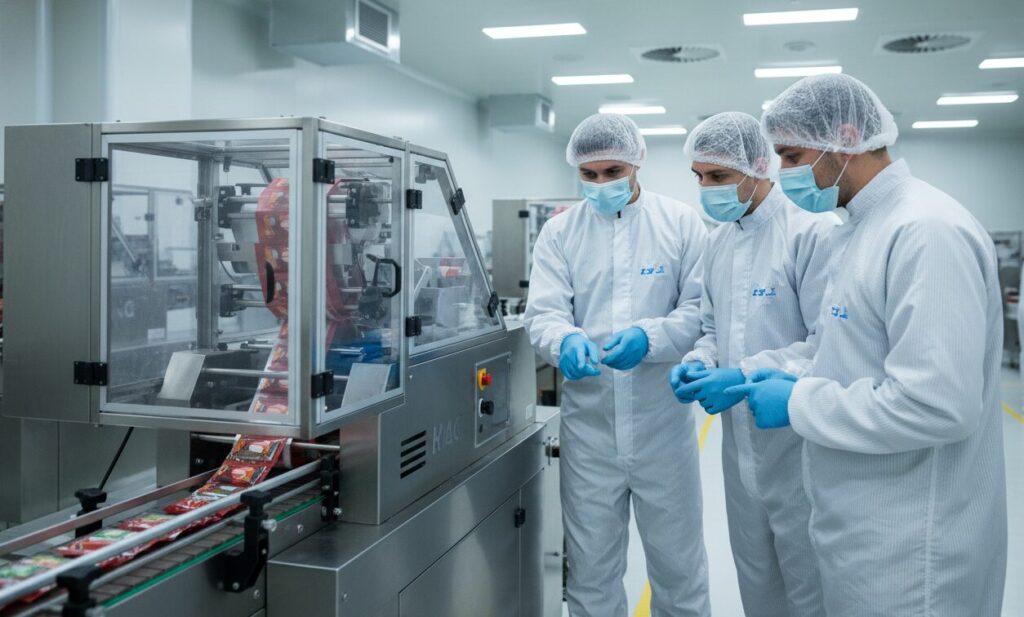

products such as throat tablets and vitamin soft candy that meet the extremely high requirements for the cleanliness of the production environment, and all stainless steel bodies and sealed transmission parts meet the production specifications of clean workshops.

01

install the packaging film on the inflatable shaft according to the film penetration diagram, and introduce it into the former through the guide roller to ensure that the film tension regulator is in the middle balance position.

02

input target bag length, sealing and cutting speed and heating temperature in HMI interface. For stored SKU, preset formula data can be directly called from menu.

03

turn on the manual turning gear to check the position of the cutter, turn on the inching function after confirmation, observe whether the photoelectric sensor accurately captures the color code, and adjust the offset.

04

after the shift, use compressed air to clean the debris of the feeding trough, and wipe the sealing knife seat with special non-woven fabric to avoid carbonization residue affecting the sealing quality.

Support a variety of heat sealing film, such as BOPP, polyester film, aluminum foil composite film, etc., the recommended thickness of 0.04 mm-0.07mm to achieve the best sealing effect.

core adjustment (such as bag length, push rod spacing) can be completed in the touch screen, if it involves the replacement of the former, the whole machine adjustment can usually be completed within 10-15 minutes.

The system is equipped with adaptive temperature control logic. When the machine decelerates or idling, it will automatically adjust the output of the heat source to ensure that the sealing quality is consistent when the residence time of the film in the heated area changes.

Yes. The machine provides standard signal interface, which can realize synchronous communication with upstream rotating material plate or vibration feeder, and realize automatic feeding and packaging.

The equipment has a built-in “no material, no package” function. If there is no candy on the feeding chain, the film pulling mechanism will automatically stop. At the same time, it can be equipped with weighing and sorting kick-off device to eliminate abnormal packaging.

The main wear and tear parts are sealing and cutting knives, heating plates and thermocouples. We use high hardness alloy cutter, normal maintenance life of up to 12 months.

This Candy Flow Wrapping Machine is specially designed for high-frequency production. With three-axis servo drive and sealing and cutting accuracy of ± 0.5mm, it achieves a stable output of up to 800 grains per minute, significantly improves the packaging automation rate and supports bulk purchases.

Packing speed:

800 pieces/minute

Film width:

within 120mm

Sealing and cutting precision:

± 0.5mm

the use of independent servo motor drive film feeding, feeding and cross-sealing, eliminating the cumulative error generated by mechanical chain transmission, so that packaging film loss reduced by 15%, extending the mechanical life of more than 5 years.

built-in high-precision sensor, real-time capture of packaging film color code displacement, automatic compensation of stretching error, to ensure that the pattern cutting position is always centered, the qualified rate of finished products reached 99.8.

all contact material parts and body shell are made of SUS304 stainless steel, in line with HACCP and FDA food safety standards, rust and corrosion resistance, support fast flushing.

the sealing system is equipped with an independent PID temperature controller, and the temperature difference fluctuation is controlled at 1 ℃. It can be adapted to BOPP, polyester film and various composite packaging materials to avoid film burning or air leakage due to uneven temperature.

the intelligent induction system automatically stops the film when detecting the material vacancy, and prevents the knife holder from cutting when the material position is offset, effectively reducing the frequency of downtime maintenance and protecting the cutter.

the optimized physical feeding path reduces the friction and damage of candy in the conveying process, and with the adjustable bag length system, the time to replace products of different specifications is shortened to 10 minutes.

| Technical Specification | Standard Value |

| Product Model | CFW-Series High Speed |

| Thin film material | BOPP, PVC, OPP/CPP, PT/PE, KSA, AL/PE |

| Packaging speed (Capacity) | 200 – 800 bags/min (depending on material size) |

| Bag Length | 40mm – 120mm |

| Bag Width | 20mm – 80mm |

| Product Height | Max. 35mm |

| Film roll diameter. | Max. 320mm |

| Machine Weight | Approximately 750kg |

| Power Supply Specifications | 220V/380V, 50/60Hz, 3.8kW |

| Machine dimensions | (L)3900mm × (W)920mm × (H)1500mm |

Fast production and stability: compared with the common frequency of 400-500 pieces/minute in the same industry, this equipment can maintain extremely low vibration value under high-speed operation of 800 pieces/minute through the cross-sealing tool holder optimized by dynamic balance, so as to ensure that the sealing strength is not reduced under long-term continuous operation and solve the efficiency bottleneck in large-scale production.

Modular quick change system: For multi-variety candy production line, this machine adopts tool-free quick disassembly design, and the former and conveyor belt can be switched in a short time. Combined with the parameter storage function of the digital touch screen, the “one-click switching” of different sizes of candy packaging is realized, which greatly improves the multi-tasking ability.

in view of the moisture absorption characteristics of hard candy and chocolate, a pressurized horizontal sealing mechanism is adopted to solve the problem of packaging air leakage caused by insufficient sealing pressure of traditional machines at high speed.

for printing packaging materials, the system has automatic calibration function, which solves the problem of incomplete pattern cutting or wrong brand logo position caused by uneven tension of packaging materials.

in view of the unstable pace of manual feeding, the system has its own material standby mode, which solves the waste of packaging materials and the labor cost of sorting empty bags caused by “running empty bags with nothing” in the traditional packaging machine.

suitable for the pursuit of the ultimate production capacity and unit energy consumption ratio of food groups, its high-speed output capacity can perfectly match the multi-channel candy molding line, to achieve full automation and seamless docking.

specially optimized for temperature-sensitive products, the heat conduction control of the sealing area is accurate, and the quality control problem of chocolate melting or surface damage during the packaging process is solved.

to meet their needs for rapid replacement of packaging specifications, one device can cover the packaging tasks of mints, chewing gum, lollipops and other small-size desserts.

products such as throat tablets and vitamin soft candy that meet the extremely high requirements for the cleanliness of the production environment, and all stainless steel bodies and sealed transmission parts meet the production specifications of clean workshops.

01

install the packaging film on the inflatable shaft according to the film penetration diagram, and introduce it into the former through the guide roller to ensure that the film tension regulator is in the middle balance position.

02

input target bag length, sealing and cutting speed and heating temperature in HMI interface. For stored SKU, preset formula data can be directly called from menu.

03

turn on the manual turning gear to check the position of the cutter, turn on the inching function after confirmation, observe whether the photoelectric sensor accurately captures the color code, and adjust the offset.

04

after the shift, use compressed air to clean the debris of the feeding trough, and wipe the sealing knife seat with special non-woven fabric to avoid carbonization residue affecting the sealing quality.

Support a variety of heat sealing film, such as BOPP, polyester film, aluminum foil composite film, etc., the recommended thickness of 0.04 mm-0.07mm to achieve the best sealing effect.

core adjustment (such as bag length, push rod spacing) can be completed in the touch screen, if it involves the replacement of the former, the whole machine adjustment can usually be completed within 10-15 minutes.

The system is equipped with adaptive temperature control logic. When the machine decelerates or idling, it will automatically adjust the output of the heat source to ensure that the sealing quality is consistent when the residence time of the film in the heated area changes.

Yes. The machine provides standard signal interface, which can realize synchronous communication with upstream rotating material plate or vibration feeder, and realize automatic feeding and packaging.

The equipment has a built-in “no material, no package” function. If there is no candy on the feeding chain, the film pulling mechanism will automatically stop. At the same time, it can be equipped with weighing and sorting kick-off device to eliminate abnormal packaging.

The main wear and tear parts are sealing and cutting knives, heating plates and thermocouples. We use high hardness alloy cutter, normal maintenance life of up to 12 months.