Search the whole station

This machine is equipped with a full servo drive system, providing up to 2500 grains/minute of double aluminum foil sealed packaging, the rejection rate is less than 0.1, perfect compliance with GMP and cGMP clean production standards, to undertake enterprise collection.

2500 grains/min

Capacity:

400 mm

Maximum width:

Control:

PLC + servo

Using PID intelligent temperature control module, the temperature control accuracy is kept within ± 1°C. This ensures that Alu/PE or paper/PE composite film is evenly heated during high-speed operation, prevents seal leakage or coking of packaging materials caused by temperature fluctuation, and increases the yield to 99.9.

Equipped with hard alloy steel slitting knife set, the service life is more than 10 million cuts. The unique self-sharpening design makes the burr on the edge of the incision <0.02mm, avoiding the phenomenon of even bags caused by poor cutting, and ensuring the neat and uniform appearance of each package.

The multi-channel vibration blanking system with photoelectric detection sensor can automatically identify and eliminate debris and empty bags. For special-shaped tablets (such as diamond, triangle), the system can control the empty pack rate within one ten thousandth, greatly reducing material waste.

All parts in contact with the drug are made of SUS316L stainless steel, which is corrosion-resistant and easy to clean, with a surface roughness of Ra < 0.4 µm. Fully meet the pharmaceutical industry strict GMP/cGMP sanitary cleaning validation requirements to prevent cross-contamination.

Through the optimized cam design and typesetting algorithm, the sealing margin between the two drugs is compressed to the limit value of 1.5mm. Compared with traditional models, each roll of packaging materials can produce 15% more finished products, saving enterprises about $5,000 per year in packaging costs.

With modular mold design, the specification switch from capsule to plain tablet can be completed in 15 minutes without special tools. The servo motor automatically calibrates the position, reducing the downtime during mold change debugging by about 80%.

| Parameter | Description |

| Product Name | Automated Strip Packaging Machine |

| Maximum production speed | 600 – 2500 pellets/minute (depending on the type) |

| Maximum packaging width | 260 mm / 400 mm (optional) |

| Applicable Packaging Materials | SP film, aluminum/polyethylene (Al/PE), paper/polyethylene, cellophane |

| Packaging thickness | Aluminum foil: 0.02-0.03mm; Composite film: 0.08mm |

| Main motor power | 1.5 kW |

| Heating power | 3.2 kW |

| Gas source pressure | 0.5 – 0.7 MPa |

| Gas consumption | ≥ 0.2 m³/min |

| Machine net weight | 1000 kg |

| External dimensions | 1800 × 1100 × 2100 mm |

| Noise level | < 75 dB |

Compared with the traditional blister packaging machine, this Automated Strip Packaging Machine adopts double-layer heat sealing technology to directly seal the medicine between two layers of aluminum foil. This structure provides superior light protection and air tightness, and the water vapor blocking efficiency is more than 30% higher than that of ordinary PVC blister, especially suitable for drugs sensitive to light and humidity. At the same time, the unit cost of packaging materials is 40% lower than that of cold-formed aluminum, which greatly reduces the expenditure of consumables for mass production.

Pain point solution: double-sided aluminum foil is used for airtight heat sealing, and the water vapor transmission rate is close to 0g/m/day, thus completely solving the problem of short storage period of hygroscopic drugs in tropical high humidity areas.

Pain point solution: the introduction of soft landing vibration feeding plate, with adjustable slideway, to solve the fragile tablets (such as effervescent tablets) in the process of high-speed blanking edge chipping and stuck material problems.

Pain point solution: through PID dynamic temperature compensation technology, the problem of unstable sealing quality caused by roller temperature lag is solved when the machine starts preheating and switches at high speed.

Suitable for mass production of aspirin, paracetamol and other light sensitive or long-term storage of drugs. The machine’s high-speed capacity and low packaging cost can significantly increase the profit margin of a single product.

For vitamin tablets, fish oil capsules and other easily oxidized products. The double aluminum packaging provides excellent antioxidant protection, and the strip packaging is light and easy to carry, which meets the needs of consumers for daily use.

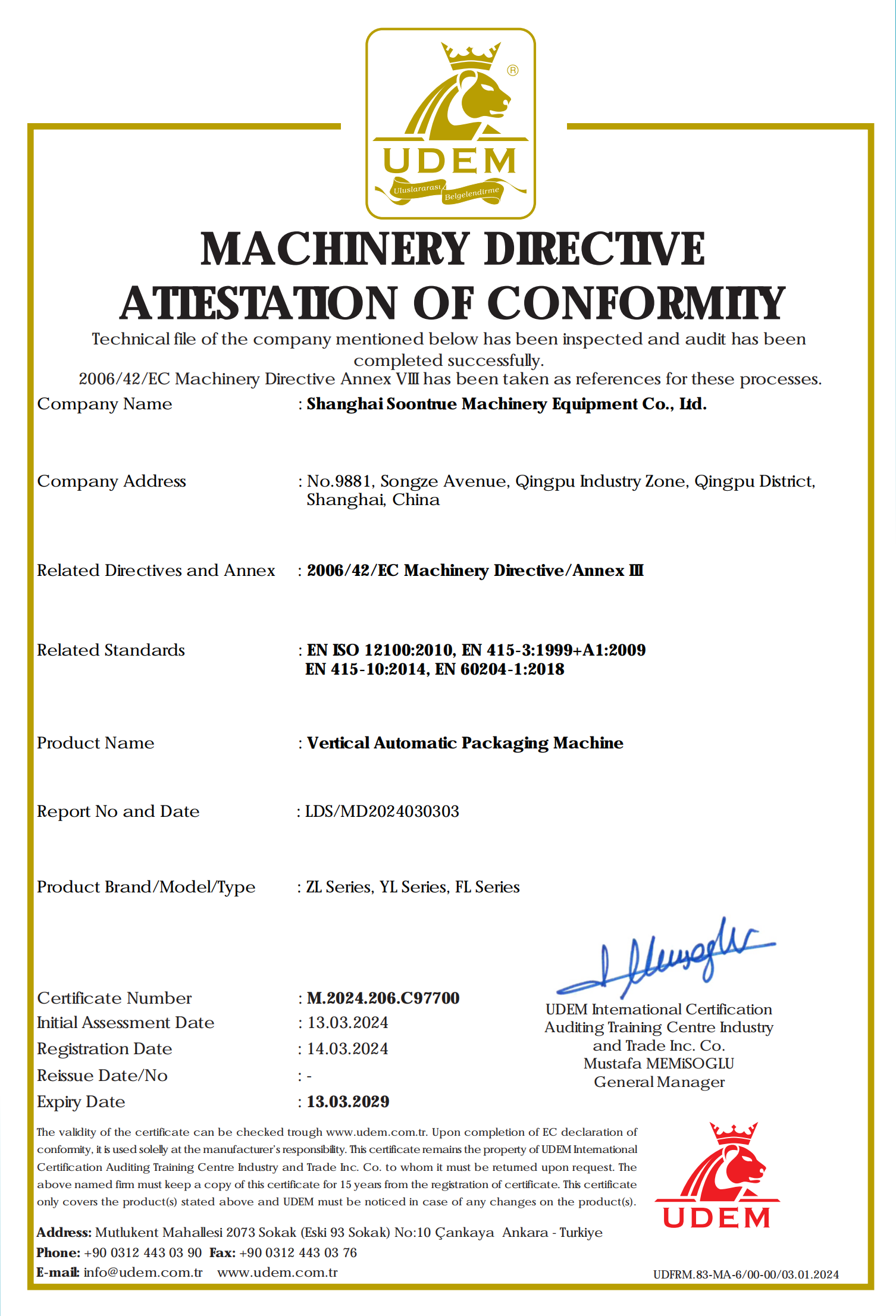

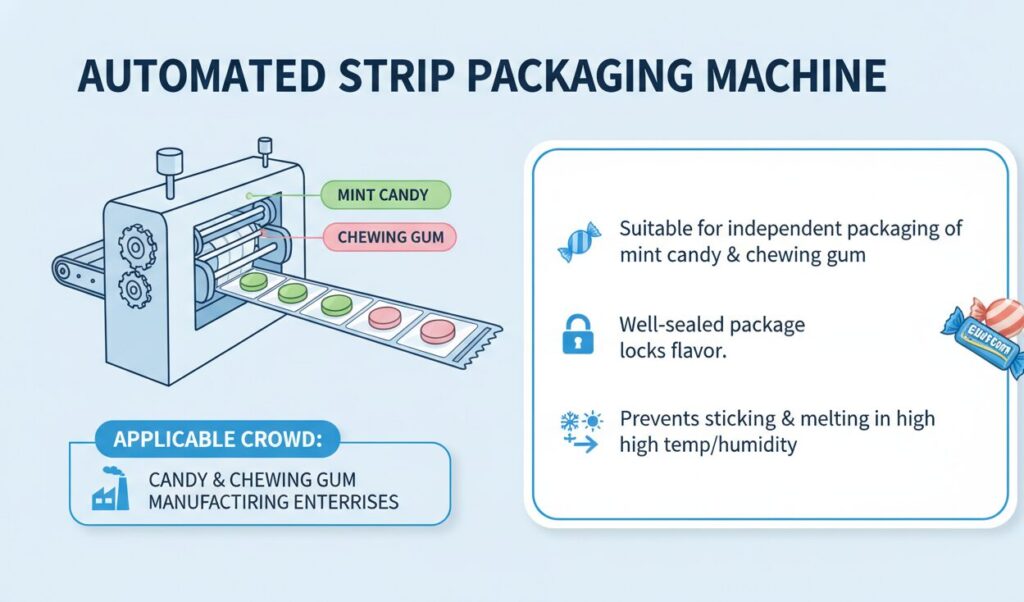

Suitable for independent packaging of mint candy and chewing gum. The well-sealed package can not only lock the candy flavor, but also prevent the sugar body from sticking and melting in high temperature and high humidity environment.

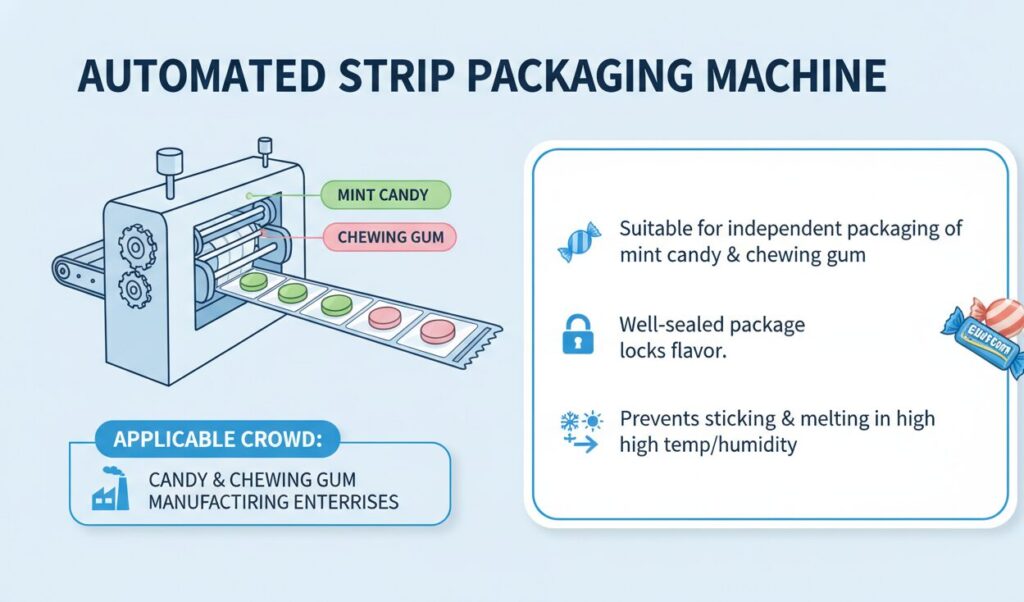

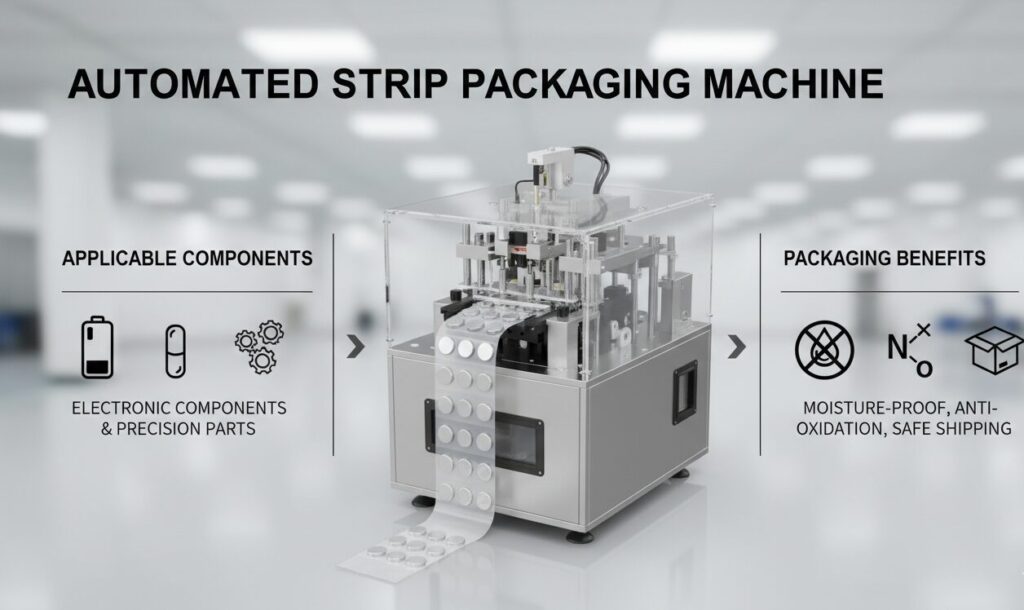

Suitable for moisture-proof and anti-oxidation packaging for button batteries, small capacitors or precision micro parts. Strip packaging can effectively prevent metal components from rusting and oxidizing during shipping.

Our factory

This machine is compatible with a variety of heat sealing materials, including 0.02-0.03mm double-sided aluminum foil, cellophane/PE, paper/PE and aluminum/PE composite film. As long as the material has a heat seal coating, it can be run on the same machine.

Support. By changing the sealing rollers and cutting knives, round, capsule or shaped tablets from Ø5mm to Ø25mm can be adapted. We provide custom mold service.

Lower maintenance costs. The strip packaging machine does not have complicated forming stations and blanking stations, and the mechanical structure is simpler. And the servo motor replaces a large number of mechanical transmission parts, and the vulnerable parts (such as heating pipes and cutters) are easy to replace and the cost is low.

Yes. The machine is equipped with an optical fiber sensor detection system. Once it detects that the tablets have not been filled into the bag, the system will record the position and automatically separate the empty bag through the waste rejection device at the discharge port to ensure that 100 percent of the finished product is qualified.

This machine is equipped with E PC(Edge Position Control) automatic correction system. The sensor monitors the edge position of the aluminum foil in real time. Once the deviation is detected, the correction motor fine-tunes the angle of the winding shaft to ensure the precise alignment of the two layers of aluminum foil.

The equipment is designed to strictly follow cGMP standards, and all contact parts are SS316L. The whole machine has passed CE safety certification and meets the requirements of ISO 9001 quality management system. The electrical components are all international first-line brands (such as Schneider, Omron).

This machine is equipped with a full servo drive system, providing up to 2500 grains/minute of double aluminum foil sealed packaging, the rejection rate is less than 0.1, perfect compliance with GMP and cGMP clean production standards, to undertake enterprise collection.

Capacity: 2500 grains/min

Maximum width: 400 mm

Control: PLC + servo

Using PID intelligent temperature control module, the temperature control accuracy is kept within ± 1°C. This ensures that Alu/PE or paper/PE composite film is evenly heated during high-speed operation, prevents seal leakage or coking of packaging materials caused by temperature fluctuation, and increases the yield to 99.9.

digital input sealing and cutting position is adopted to ensure that the color code tracking error is less than 1mm under high-speed operation, the packaging finished product pattern is complete, and the defective rate is reduced to less than 0.3.

All parts in contact with the drug are made of SUS316L stainless steel, which is corrosion-resistant and easy to clean, with a surface roughness of Ra < 0.4 µm. Fully meet the pharmaceutical industry strict GMP/cGMP sanitary cleaning validation requirements to prevent cross-contamination.

The multi-channel vibration blanking system with photoelectric detection sensor can automatically identify and eliminate debris and empty bags. For special-shaped tablets (such as diamond, triangle), the system can control the empty pack rate within one ten thousandth, greatly reducing material waste.

With modular mold design, the specification switch from capsule to plain tablet can be completed in 15 minutes without special tools. The servo motor automatically calibrates the position, reducing the downtime during mold change debugging by about 80%.

Through the optimized cam design and typesetting algorithm, the sealing margin between the two drugs is compressed to the limit value of 1.5mm. Compared with traditional models, each roll of packaging materials can produce 15% more finished products, saving enterprises about $5,000 per year in packaging costs.

| Parameter | Description |

| Product Name | Automated Strip Packaging Machine |

| Maximum production speed | 600 – 2500 pellets/minute (depending on the type) |

| Maximum packaging width | 260 mm / 400 mm (optional) |

| Applicable Packaging Materials | SP film, aluminum/polyethylene (Al/PE), paper/polyethylene, cellophane |

| Packaging thickness | Aluminum foil: 0.02-0.03mm; Composite film: 0.08mm |

| Main motor power | 1.5 kW |

| Heating power | 3.2 kW |

| Gas source pressure | 0.5 – 0.7 MPa |

| Gas consumption | ≥ 0.2 m³/min |

| Machine net weight | 1000 kg |

| External dimensions | 1800 × 1100 × 2100 mm |

| Noise level | < 75 dB |

Compared with the traditional blister packaging machine, this Automated Strip Packaging Machine adopts double-layer heat sealing technology to directly seal the medicine between two layers of aluminum foil. This structure provides superior light protection and air tightness, and the water vapor blocking efficiency is more than 30% higher than that of ordinary PVC blister, especially suitable for drugs sensitive to light and humidity. At the same time, the unit cost of packaging materials is 40% lower than that of cold-formed aluminum, which greatly reduces the expenditure of consumables for mass production.

Pain point solution: double-sided aluminum foil is used for airtight heat sealing, and the water vapor transmission rate is close to 0g/m/day, thus completely solving the problem of short storage period of hygroscopic drugs in tropical high humidity areas.

Pain point solution: the introduction of soft landing vibration feeding plate, with adjustable slideway, to solve the fragile tablets (such as effervescent tablets) in the process of high-speed blanking edge chipping and stuck material problems.

Pain point solution: through PID dynamic temperature compensation technology, the problem of unstable sealing quality caused by roller temperature lag is solved when the machine starts preheating and switches at high speed.

Suitable for mass production of aspirin, paracetamol and other light sensitive or long-term storage of drugs. The machine’s high-speed capacity and low packaging cost can significantly increase the profit margin of a single product.

For vitamin tablets, fish oil capsules and other easily oxidized products. The double aluminum packaging provides excellent antioxidant protection, and the strip packaging is light and easy to carry, which meets the needs of consumers for daily use.

Suitable for independent packaging of mint candy and chewing gum. The well-sealed package can not only lock the candy flavor, but also prevent the sugar body from sticking and melting in high temperature and high humidity environment.

Suitable for moisture-proof and anti-oxidation packaging for button batteries, small capacitors or precision micro parts. Strip packaging can effectively prevent metal components from rusting and oxidizing during shipping.

This machine is compatible with a variety of heat sealing materials, including 0.02-0.03mm double-sided aluminum foil, cellophane/PE, paper/PE and aluminum/PE composite film. As long as the material has a heat seal coating, it can be run on the same machine.

Support. By changing the sealing rollers and cutting knives, round, capsule or shaped tablets from Ø5mm to Ø25mm can be adapted. We provide custom mold service.

Lower maintenance costs. The strip packaging machine does not have complicated forming stations and blanking stations, and the mechanical structure is simpler. And the servo motor replaces a large number of mechanical transmission parts, and the vulnerable parts (such as heating pipes and cutters) are easy to replace and the cost is low.

Yes. The machine is equipped with an optical fiber sensor detection system. Once it detects that the tablets have not been filled into the bag, the system will record the position and automatically separate the empty bag through the waste rejection device at the discharge port to ensure that 100 percent of the finished product is qualified.

This machine is equipped with E PC(Edge Position Control) automatic correction system. The sensor monitors the edge position of the aluminum foil in real time. Once the deviation is detected, the correction motor fine-tunes the angle of the winding shaft to ensure the precise alignment of the two layers of aluminum foil.

The equipment is designed to strictly follow cGMP standards, and all contact parts are SS316L. The whole machine has passed CE safety certification and meets the requirements of ISO 9001 quality management system. The electrical components are all international first-line brands (such as Schneider, Omron).