Search the whole station

The flow wrapping machine for sale adopts a double frequency conversion/servo control system, with a packaging speed of up to 230 packs/minute and a sealing and cutting accuracy within 1mm. It is the first choice for automatic packaging of food, medicine and daily necessities, and supports bulk purchases.

the bag length is set and cut, no need to manually adjust the empty walk, compared to the traditional packaging machine can save about 15% of the packaging material loss, greatly reduce the packaging cost of a single product

digital input sealing and cutting position is adopted to ensure that the color code tracking error is less than 1mm under high-speed operation, the packaging finished product pattern is complete, and the defective rate is reduced to less than 0.3.

the temperature control accuracy is as high as 1 ℃, which can be perfectly adapted to various thicknesses of packaging materials such as OPP, PE, composite film, etc. to ensure tight, smooth sealing and no burning shrinkage.

the operating status of the equipment is displayed on the screen in real time. In case of abnormality, the fault point can be accurately located, the average maintenance time (MTTR) is shortened by about 40%, and the continuous operation of the production line is guaranteed.

the sensor monitors the material position in real time, and automatically stops sealing and cutting in case of misalignment, preventing damage to the product and protecting the cutter from hard object impact, thus prolonging the service life of the cutter for more than 2 years.

the mechanical transmission chain is simplified, the operating noise is less than 75dB, the gear wear point is reduced by 80%, and the mechanical stability of the equipment under high-strength operation is significantly improved.

| Technical Specifications | Standard configuration data (Standard Value) |

| Packing Capacity | 40 – 230 bags/min |

| Packaging film width | Max. 350mm |

| Bag Length | 65 – 330mm |

| Bag Width | 30 – 150mm |

| Product Height | Max. 60mm |

| Film Roll Diameter | Max. 320mm |

| Power Supply Specifications | 220V, 50/60Hz, 2.4KW |

| Machine Weight | 550kg |

| Machine dimensions | (L)4020 x (W)720 x (H)1320mm |

This product adopts advanced cantilever frame design, compared with the closed base of similar products, it is more convenient to clean up the scattered residue, in line with GMP health standards. At the same time, its core driving parts are made of legal/Japanese brand, which ensures the dynamic balance under 24-hour continuous operation, and the mechanical vibration is reduced by 30% compared with conventional models.

aiming at the long-distance machine adjustment loss caused by switching between new and old batch of package materials, one-key production exchange is realized through parameter memory function, thus solving the problem of time-consuming and material-consuming machine adjustment.

for fragile products such as biscuits and chocolate, the running track of the pushing finger is optimized, and the industry pain point of easy crushing of products under high-speed packaging is solved through slow feeding technology.

in view of the difficulty in recruiting professional operators, an intuitive 7-inch full-color touch screen is integrated, and novices can skillfully complete daily operations and parameter fine-tuning in only 10 minutes of training.

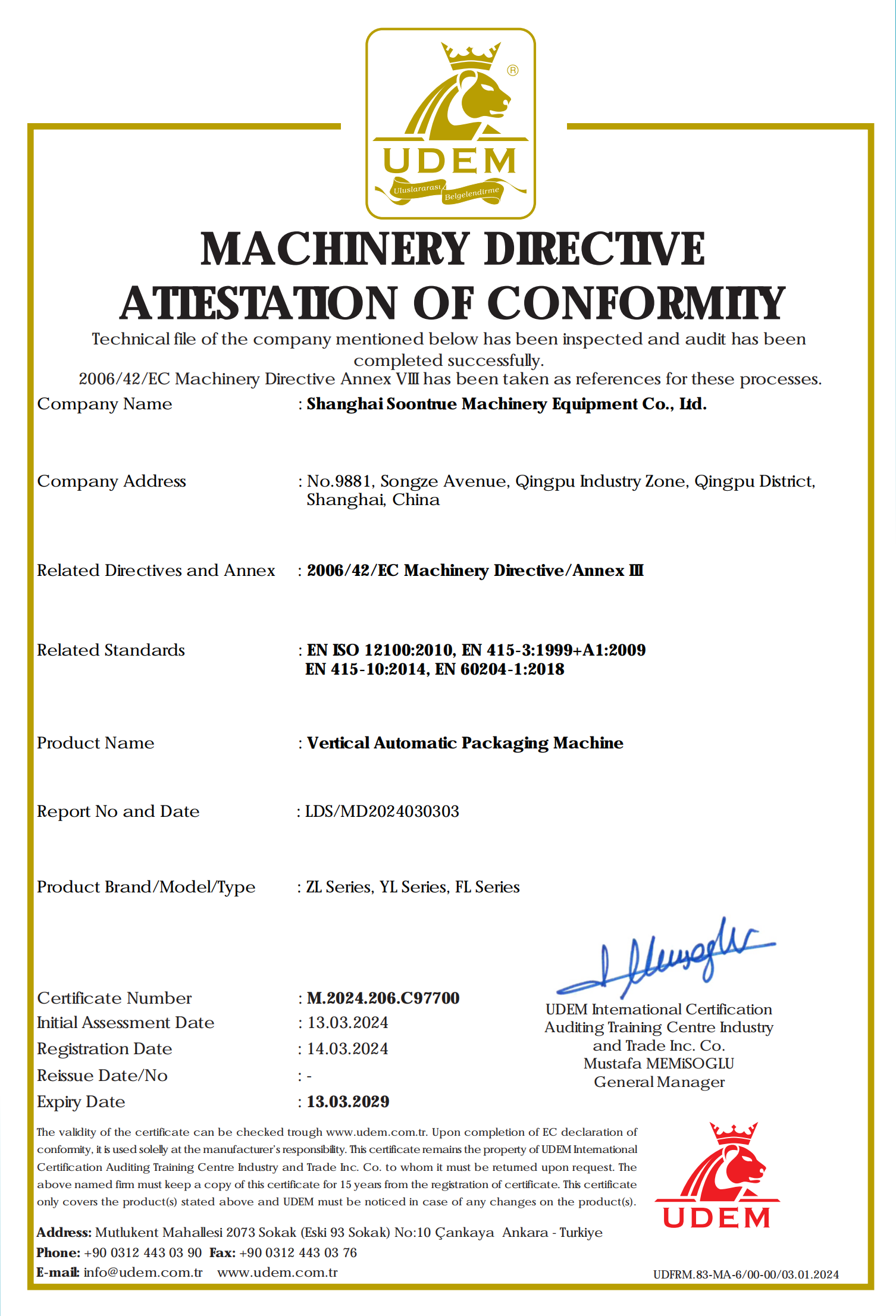

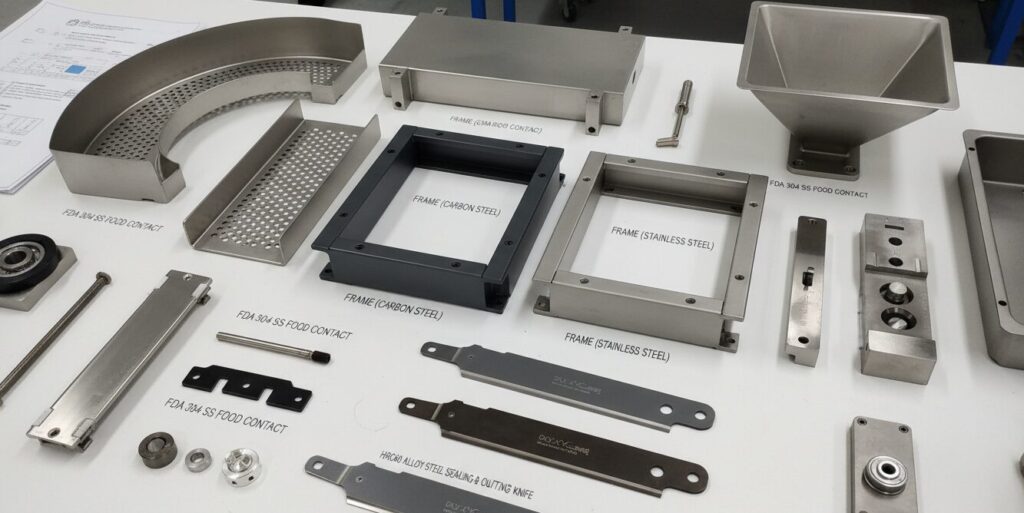

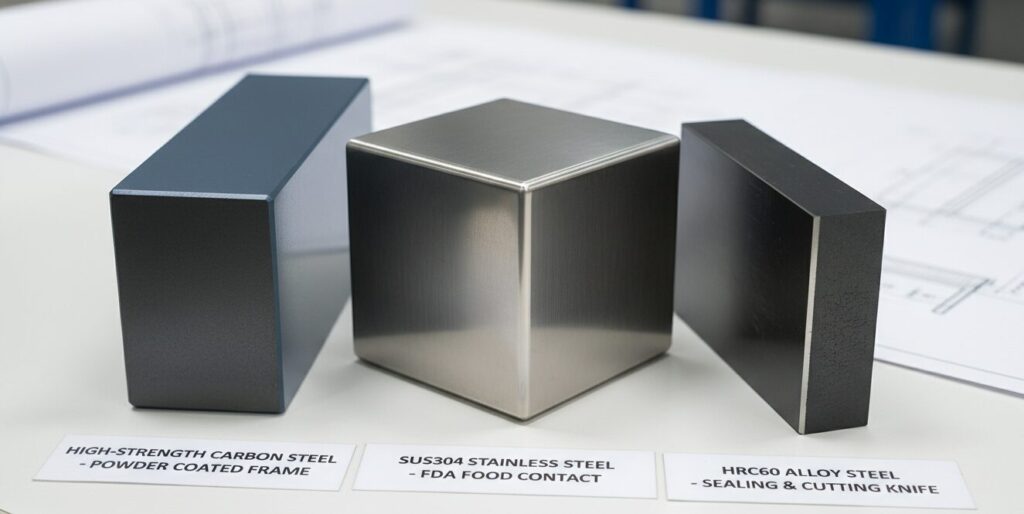

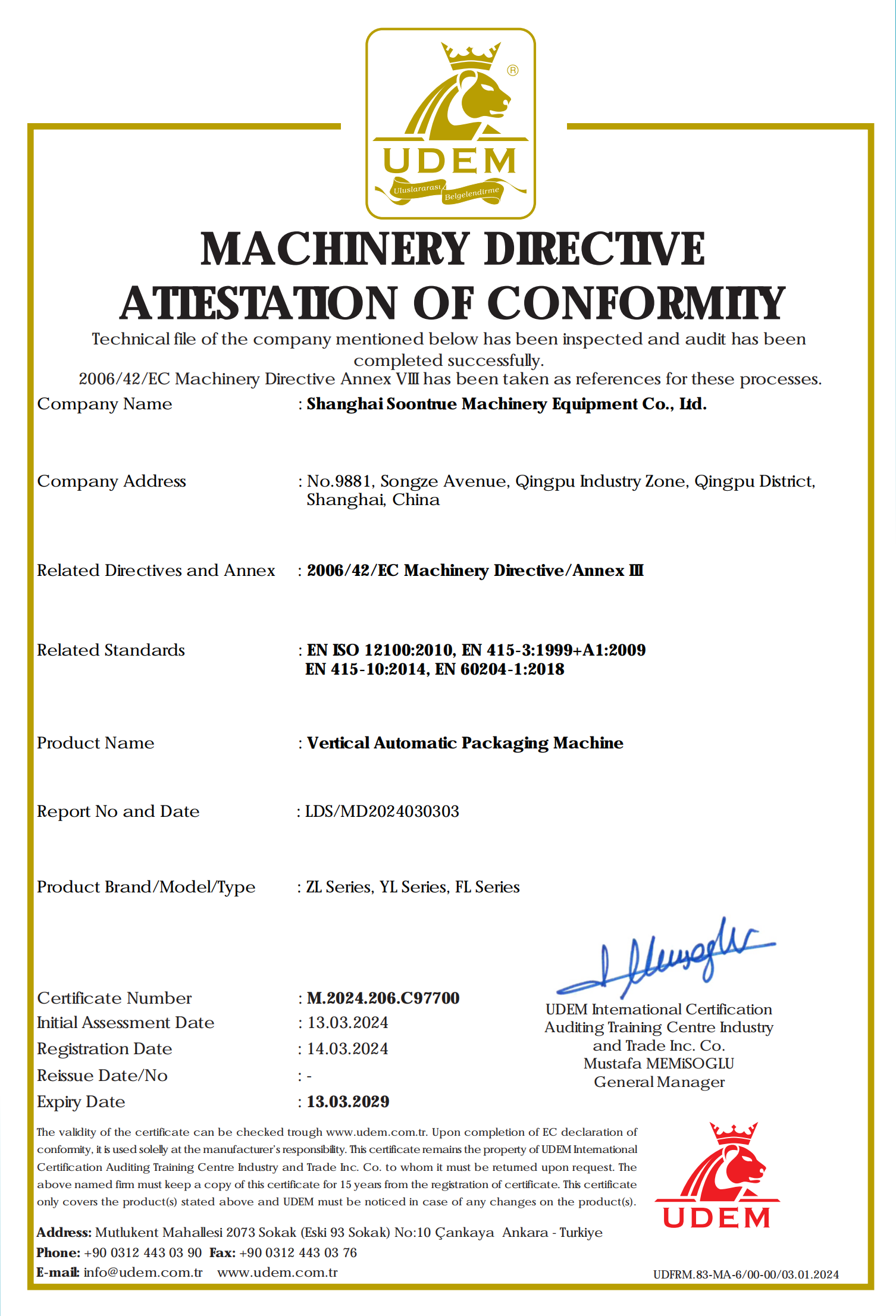

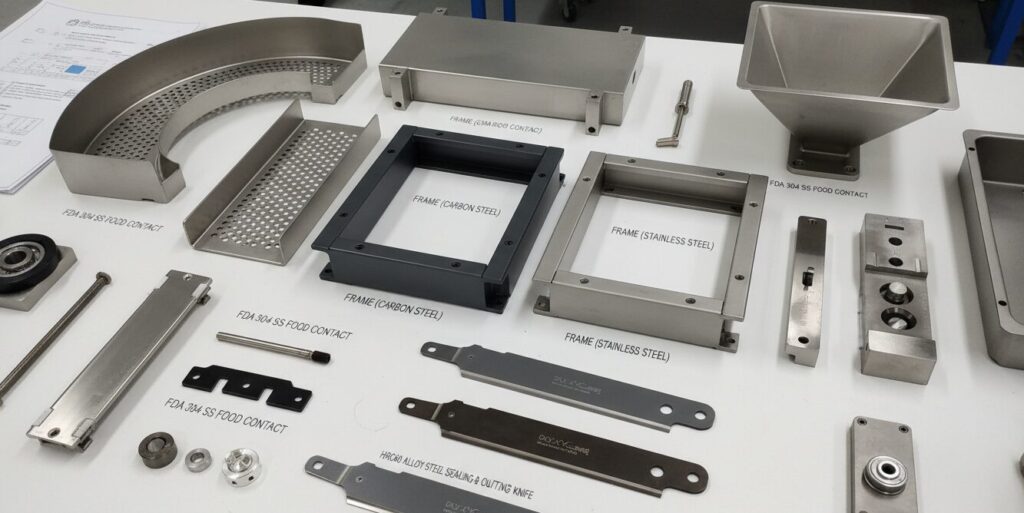

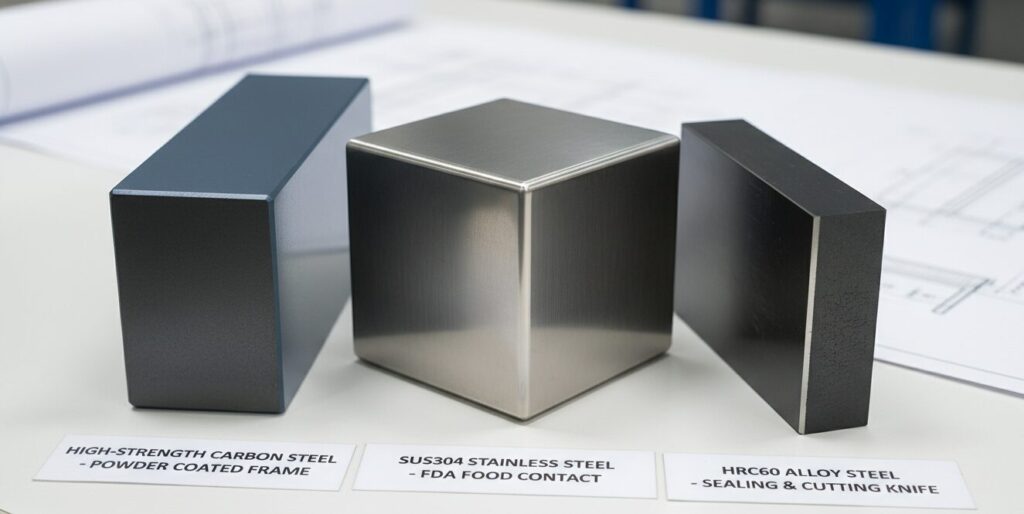

The fuselage frame is made of high-strength carbon steel spraying or SUS304 stainless steel (optional), and all food contact parts are made of 304 stainless steel that meets FDA standards. The sealing and cutting tool is made of special alloy steel, quenched by vacuum heat treatment, with a hardness of HRC60, ensuring long-term wear resistance and smooth incision.

Our factory

This machine is compatible with most heat-sealed composite materials, such as OPP/CPP, PT/PE, KSA/PE, OPP/AL/PE, etc. The film thickness is recommended to be between 0.03mm and 0.07mm.

Thanks to the adjustable design of the former and the parameter storage function of the touch screen, skilled operators can usually switch specifications within 5-10 minutes.

Yes, the equipment has reserved a mounting bracket and a synchronization signal interface, and can be equipped with a thermal transfer printer, an ink wheel printer or an automatic labeling system according to requirements.

conveyor belt and work surface are made of stainless steel and easy to disassemble design, daily production after the end of the available wet cloth to quickly wipe, in line with food processing safety standards.

The main wearing parts include heating plate, thermocouple, cutter and transmission belt. We randomly attach a set of vulnerable parts spare package to ensure that the production line does not stop.

We provide detailed video installation tutorial and remote technical support. For large-scale integration projects, senior engineers can be dispatched to provide on-site commissioning and personnel training as required.

The flow wrapping machine for sale adopts a double frequency conversion/servo control system, with a packaging speed of up to 230 packs/minute and a sealing and cutting accuracy within 1mm. It is the first choice for automatic packaging of food, medicine and daily necessities, and supports bulk purchases.

Speed 230 pieces/min

Maximum film width 350mm

304 stainless steel material

the bag length is set and cut, no need to manually adjust the empty walk, compared to the traditional packaging machine can save about 15% of the packaging material loss, greatly reduce the packaging cost of a single product.

digital input sealing and cutting position is adopted to ensure that the color code tracking error is less than 1mm under high-speed operation, the packaging finished product pattern is complete, and the defective rate is reduced to less than 0.3.

the temperature control accuracy is as high as 1 ℃, which can be perfectly adapted to various thicknesses of packaging materials such as OPP, PE, composite film, etc. to ensure tight, smooth sealing and no burning shrinkage.

the operating status of the equipment is displayed on the screen in real time. In case of abnormality, the fault point can be accurately located, the average maintenance time (MTTR) is shortened by about 40%, and the continuous operation of the production line is guaranteed.

the sensor monitors the material position in real time, and automatically stops sealing and cutting in case of misalignment, preventing damage to the product and protecting the cutter from hard object impact, thus prolonging the service life of the cutter for more than 2 years.

the mechanical transmission chain is simplified, the operating noise is less than 75dB, the gear wear point is reduced by 80%, and the mechanical stability of the equipment under high-strength operation is significantly improved.

| Technical Specifications | Standard configuration data (Standard Value) |

| Packing Capacity | 40 – 230 bags/min |

| Packaging film width | Max. 350mm |

| Bag Length | 65 – 330mm |

| Bag Width | 30 – 150mm |

| Product Height | Max. 60mm |

| Film Roll Diameter | Max. 320mm |

| Power Supply Specifications | 220V, 50/60Hz, 2.4KW |

| Machine Weight | 550kg |

| Machine dimensions | (L)4020 x (W)720 x (H)1320mm |

This product adopts advanced cantilever frame design, compared with the closed base of similar products, it is more convenient to clean up the scattered residue, in line with GMP health standards. At the same time, its core driving parts are made of legal/Japanese brand, which ensures the dynamic balance under 24-hour continuous operation, and the mechanical vibration is reduced by 30% compared with conventional models.

aiming at the long-distance machine adjustment loss caused by switching between new and old batch of package materials, one-key production exchange is realized through parameter memory function, thus solving the problem of time-consuming and material-consuming machine adjustment.

for fragile products such as biscuits and chocolate, the running track of the pushing finger is optimized, and the industry pain point of easy crushing of products under high-speed packaging is solved through slow feeding technology.

in view of the difficulty in recruiting professional operators, an intuitive 7-inch full-color touch screen is integrated, and novices can skillfully complete daily operations and parameter fine-tuning in only 10 minutes of training.

The fuselage frame is made of high-strength carbon steel spraying or SUS304 stainless steel (optional), and all food contact parts are made of 304 stainless steel that meets FDA standards. The sealing and cutting tool is made of special alloy steel, quenched by vacuum heat treatment, with a hardness of HRC60, ensuring long-term wear resistance and smooth incision.

This machine is compatible with most heat-sealed composite materials, such as OPP/CPP, PT/PE, KSA/PE, OPP/AL/PE, etc. The film thickness is recommended to be between 0.03mm and 0.07mm.

Thanks to the adjustable design of the former and the parameter storage function of the touch screen, skilled operators can usually switch specifications within 5-10 minutes.

Yes, the equipment has reserved a mounting bracket and a synchronization signal interface, and can be equipped with a thermal transfer printer, an ink wheel printer or an automatic labeling system according to requirements.

conveyor belt and work surface are made of stainless steel and easy to disassemble design, daily production after the end of the available wet cloth to quickly wipe, in line with food processing safety standards.

The main wearing parts include heating plate, thermocouple, cutter and transmission belt. We randomly attach a set of vulnerable parts spare package to ensure that the production line does not stop.

We provide detailed video installation tutorial and remote technical support. For large-scale integration projects, senior engineers can be dispatched to provide on-site commissioning and personnel training as required.