Search the whole station

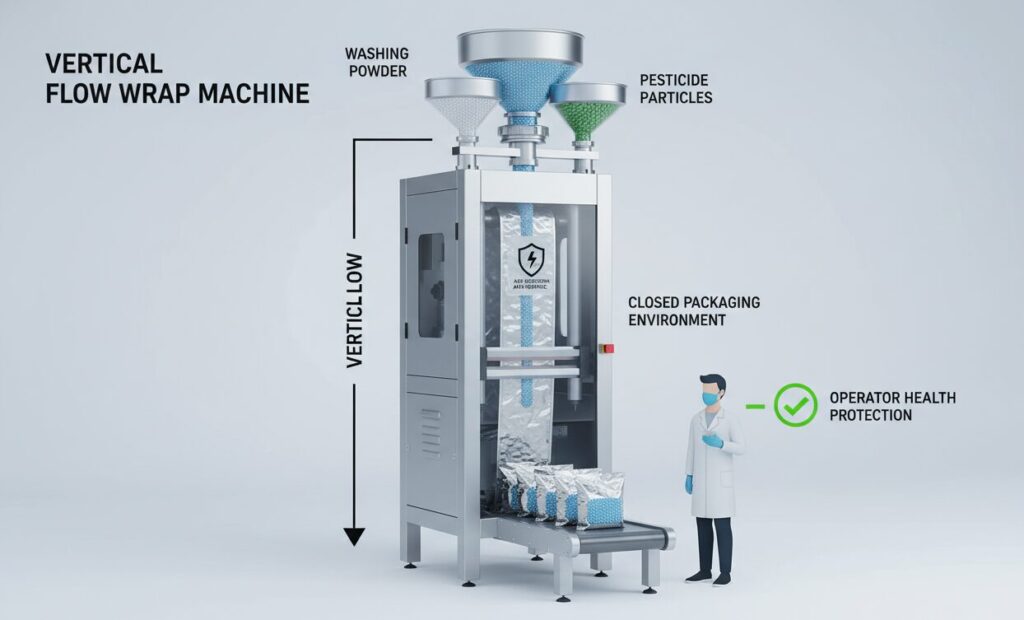

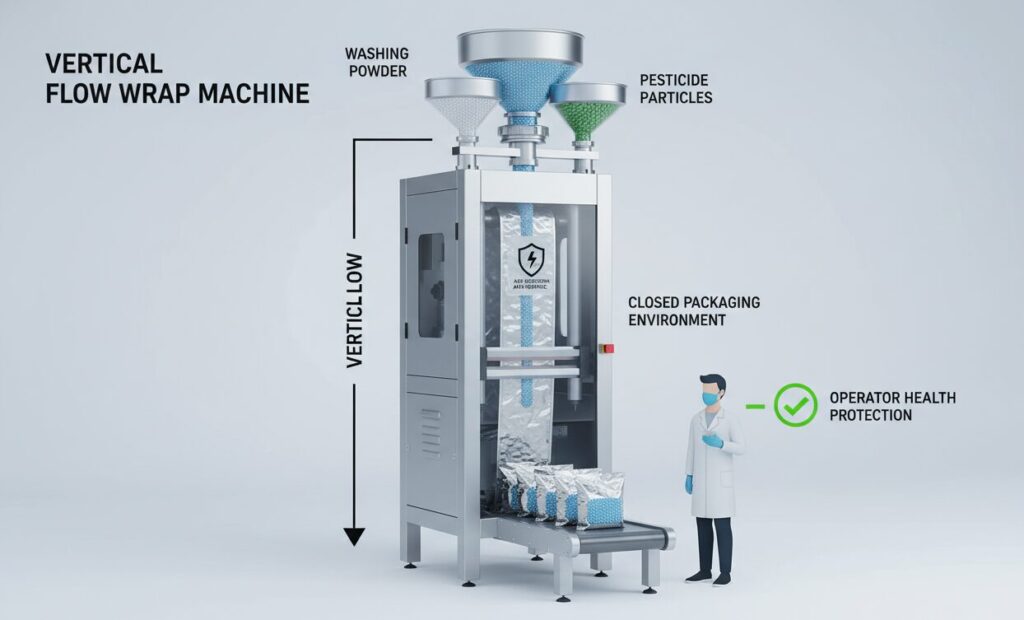

Vertical Flow Wrap Machine is the 1 high-speed automatic equipment that uses the principle of gravity blanking and integrates bag making, filling, sealing and cutting. It is specially designed to provide compact and high-precision packaging solutions for powder, granules and bulk materials. The supply of goods is sufficient and the manufacturers supply them directly.

30-120 bags/min

maximum 420mm

± 0.5-1%

using double servo motor to control the film, the positioning accuracy of bag length can reach 0.2mm, greatly reduce the pattern dislocation caused by tensile deformation, and reduce the loss of packaging materials by about 5% every year.

independent control of longitudinal seal and transverse seal temperature, the fluctuation range is controlled within ± 1 ℃, to ensure that BOPP or composite film of different thickness still has 100% air tightness under high-speed operation.

Compared with horizontal packaging machines, its footprint is reduced by about 60%, which can realize multi-line parallel arrangement in limited workshop space, significantly increasing the output value of the plant per square meter.

the built-in 7-inch industrial touch screen supports storing up to 50 sets of product parameters. When changing specifications, only one key call is required, and the adjustment time is shortened from the traditional 40 minutes to less than 10 minutes.

The main structure is made of 304 stainless steel, and the key parts have IP65 protection level, which supports direct washing, effectively prevents dust accumulation and meets GMP food hygiene and safety standards.

supports seamless docking with combination scales, screw metering machines or measuring cup filling machines, realizing cross-category compatibility from hardware to ultra-fine powder, and improving the utilization rate of equipment assets.

| Parameter Items | Technical Specifications |

| Machine Model | VFW-420 Series |

| Maximum film width | 420 mm |

| Bag length | 80 – 300 mm |

| Bag width | 60 – 200 mm |

| Packaging speed | 30 – 120 bags/min (depending on material) |

| outer diameter of roll | Max. 320 mm |

| Power specifications | 220V, 50/60Hz, 3.0KW |

| Machine weight | Approximately 550 kg |

| Gas source pressure | 0.6 Mpa, 0.35m³/min |

through the high-frequency swing device and precision pressure adjustment of the sealing jaw, the sealing caused by the clamping of powder products at the sealing is solved, and the leakage rate is reduced to less than 0.1.

automatic centering sensing bracket is configured to correct film deviation in real time, thus solving sealing skew and visual defects caused by uneven coil quality.

The use of oil-free lubricated bearings and modular circuit design extends the daily maintenance cycle from once a week to once a month, improving the start-up rate of large factories.

through the design of the quick-release former (Bag Former), a single person can complete the bag width replacement within 3 minutes, thus solving the efficiency bottleneck of multi-variety small batch order switching.

suitable for high-speed quantitative packaging of puffed food, nuts, candy and frozen food, ensuring stable output and bagging aesthetics during peak production periods.

specially designed for washing powder, desiccant, pesticide particles, etc., to provide anti-corrosion, anti-static closed packaging environment, to protect the health of operators.

for Chinese medicine tablets, granule granules and medical consumables, to meet the high compliance requirements of aseptic production and material tracking.

for screws, plastic parts, electronic components of the automatic piece packaging, to solve the manual bagging speed is slow, error-prone and costly pain points.

install the roll film on the bracket and lead it to the former according to the path of the guide roller to ensure that the tension adjustment rod is in the balance position.

enter the target bag length, sealing temperature (recommended 130-160 ℃) and blanking delay time on the HMI screen.

open the “Jog” mode, check whether the bag shape and color code tracking are aligned in a single run, and switch to automatic after confirmation.

after each shift, use copper brush to clean the residue of sealing jaw, and regularly check whether the air source filter cup is accumulated.

Innovation in Production: Precision and Efficiency at Scale.

The standard configuration supports a pillow bag (Pillow Bag), and a gusset bag (Gusset Bag), perforated bag or even bag can be realized by changing accessories. [2]

We are equipped with a closed feeding pipe and a dust collection interface, combined with a vacuum suction device, which can effectively control fine dust entering the sealing area.

Support a variety of heat-sealed composite films, such as PET/AL/PE, PET/PE, NY/AL/PE, etc. The thickness is recommended to be between 0.04-0.09mm.

The servo control can compensate the length error in real time according to the feedback, run more smoothly, have low noise, and avoid the bag length difference caused by air pressure fluctuation.

Using quick-fitting buckle design, skilled operators can usually complete the replacement and alignment of different width formers within 5 minutes.

The machine supports two modes of switching between “fixed length” and “color code”. If the sensor is abnormal, it can temporarily switch to fixed length mode to maintain production and carry out cleaning and maintenance.

Vertical Flow Wrap Machine is the 1 high-speed automatic equipment that uses the principle of gravity blanking and integrates bag making, filling, sealing and cutting. It is specially designed to provide compact and high-precision packaging solutions for powder, granules and bulk materials. The supply of goods is sufficient and the manufacturers supply them directly.

30-120 bags/min

maximum 420mm

± 0.5-1%

using double servo motor to control the film, the positioning accuracy of bag length can reach 0.2mm, greatly reduce the pattern dislocation caused by tensile deformation, and reduce the loss of packaging materials by about 5% every year.

independent control of longitudinal seal and transverse seal temperature, the fluctuation range is controlled within ± 1 ℃, to ensure that BOPP or composite film of different thickness still has 100% air tightness under high-speed operation.

Compared with horizontal packaging machines, its footprint is reduced by about 60%, which can realize multi-line parallel arrangement in limited workshop space, significantly increasing the output value of the plant per square meter.

the built-in 7-inch industrial touch screen supports storing up to 50 sets of product parameters. When changing specifications, only one key call is required, and the adjustment time is shortened from the traditional 40 minutes to less than 10 minutes.

The main structure is made of 304 stainless steel, and the key parts have IP65 protection level, which supports direct washing, effectively prevents dust accumulation and meets GMP food hygiene and safety standards.

supports seamless docking with combination scales, screw metering machines or measuring cup filling machines, realizing cross-category compatibility from hardware to ultra-fine powder, and improving the utilization rate of equipment assets.

| Parameter Items | Technical Specifications |

| Machine Model | VFW-420 Series |

| Maximum film width | 420 mm |

| Bag length | 80 – 300 mm |

| Bag width | 60 – 200 mm |

| Packaging speed | 30 – 120 bags/min (depending on material) |

| outer diameter of roll | Max. 320 mm |

| Power specifications | 220V, 50/60Hz, 3.0KW |

| Machine weight | Approximately 550 kg |

| Gas source pressure | 0.6 Mpa, 0.35m³/min |

through the high-frequency swing device and precision pressure adjustment of the sealing jaw, the sealing caused by the clamping of powder products at the sealing is solved, and the leakage rate is reduced to less than 0.1.

automatic centering sensing bracket is configured to correct film deviation in real time, thus solving sealing skew and visual defects caused by uneven coil quality.

The use of oil-free lubricated bearings and modular circuit design extends the daily maintenance cycle from once a week to once a month, improving the start-up rate of large factories.

through the design of the quick-release former (Bag Former), a single person can complete the bag width replacement within 3 minutes, thus solving the efficiency bottleneck of multi-variety small batch order switching.

suitable for high-speed quantitative packaging of puffed food, nuts, candy and frozen food, ensuring stable output and bagging aesthetics during peak production periods.

specially designed for washing powder, desiccant, pesticide particles, etc., to provide anti-corrosion, anti-static closed packaging environment, to protect the health of operators.

for Chinese medicine tablets, granule granules and medical consumables, to meet the high compliance requirements of aseptic production and material tracking.

for screws, plastic parts, electronic components of the automatic piece packaging, to solve the manual bagging speed is slow, error-prone and costly pain points.

install the roll film on the bracket and lead it to the former according to the path of the guide roller to ensure that the tension adjustment rod is in the balance position.

enter the target bag length, sealing temperature (recommended 130-160 ℃) and blanking delay time on the HMI screen.

open the “Jog” mode, check whether the bag shape and color code tracking are aligned in a single run, and switch to automatic after confirmation.

after each shift, use copper brush to clean the residue of sealing jaw, and regularly check whether the air source filter cup is accumulated.

The standard configuration supports a pillow bag (Pillow Bag), and a gusset bag (Gusset Bag), perforated bag or even bag can be realized by changing accessories. [2]

We are equipped with a closed feeding pipe and a dust collection interface, combined with a vacuum suction device, which can effectively control fine dust entering the sealing area.

Support a variety of heat-sealed composite films, such as PET/AL/PE, PET/PE, NY/AL/PE, etc. The thickness is recommended to be between 0.04-0.09mm.

The servo control can compensate the length error in real time according to the feedback, run more smoothly, have low noise, and avoid the bag length difference caused by air pressure fluctuation.

Using quick-fitting buckle design, skilled operators can usually complete the replacement and alignment of different width formers within 5 minutes.

The machine supports two modes of switching between “fixed length” and “color code”. If the sensor is abnormal, it can temporarily switch to fixed length mode to maintain production and carry out cleaning and maintenance.