Search the whole station

Our Eco Friendly Packaging Machines is specially developed for biodegradable materials and recycled paper. Through the integration of energy-saving servo system and high-precision heat sealing technology, it can reduce 30% of production energy consumption and realize 100% green packaging replacement. The supply capacity is sufficient to support batch placing orders.

Compatible with 100% degradable materials

± 0.5mm high precision servo sealing and cutting

Reduce energy consumption by more than 25%

| Parameter Items | Technical Specifications |

| Applicable Packaging Materials | PLA, PBAT, compostable film, recycled paper, water-based coated paper |

| Packaging speed | 40 – 120 packs/minute (depending on product size) |

| Bag length/width | Length: 50-400mm / Width: 50-300mm |

| Sealing and cutting accuracy | ±0.5 mm (servo drive control) |

| Rated power | 4.5 kW – 7.5 kW (Energy-efficient design) |

| Working air pressure | 0.6 – 0.8 MPa |

| control system | 10-inch touchscreen + PLC modular control |

| Noise reduction level | < 75 dB (meets industrial quiet room standards) |

| Overall material | SUS304 stainless steel (meets food-grade and environmental standards) |

this eco friendly packaging machines adopts advanced dynamic simulation design, which can maintain extremely high sealing consistency under high-speed operation. its core advantage lies in the precise temperature control (error ± 1 ℃) of temperature-sensitive biological materials, avoiding the common problems of sealing scorching or poor sealing of traditional equipment. In addition, the modular rapid mold change system equipped with the equipment shortens the switching time between different environmentally friendly materials by 50%, greatly improving the flexibility of multi-species and small batch production.

in view of the low physical strength of environmentally friendly film, the multi-stage servo tension adjustment system is adopted to solve the problem of pattern dislocation and size deviation caused by material stretching deformation during transportation.

through the integration of power feedback and frequency conversion optimization algorithm, the problem of serious power waste in intermittent production of traditional packaging lines is solved, and the energy efficiency ratio of single-piece packaging is increased by more than 20%.

the use of intelligent PID constant temperature control combined with Teflon anti-adhesive coating sealing knife solves the industry problem that heat-sensitive materials such as PLA are easy to stick to the knife, wire drawing or brittle cracking at the sealing part during sealing and cutting.

the built-in real-time tracking system of production data solves the problem that the purchaser cannot provide accurate energy consumption and waste data in the packaging process when applying for green factories or carbon neutral projects.

suitable for the pursuit of zero plastic packaging FMCG brand, can handle fruit shell paper, biofilm and other packaging, enhance the product green brand image and meet the global plastic reduction regulations.

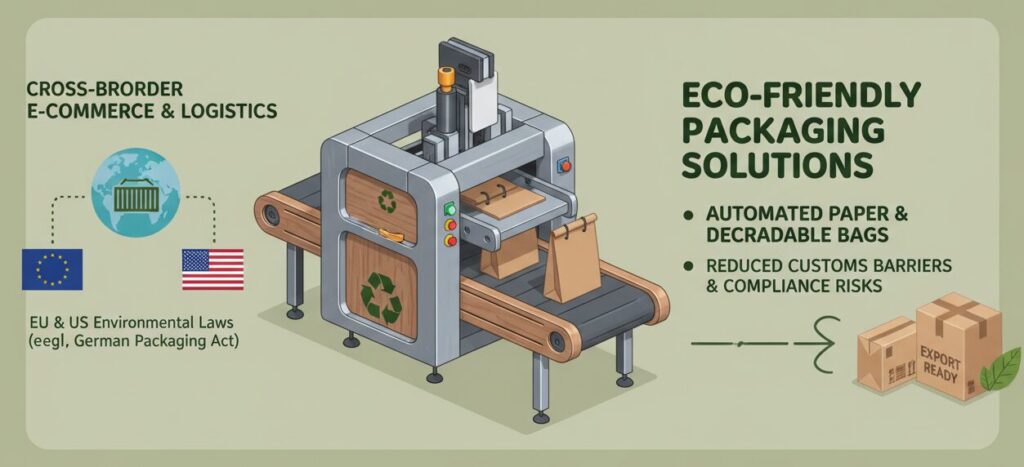

to provide automated paper bags and degradation bag packaging solutions for exporters who need to deal with stringent environmental packaging laws in Europe and the United States (such as the German packaging law) to avoid export compliance risks and reduce customs clearance barriers.

to meet the demand of aseptic production of non-toxic and recyclable packaging for medical devices or skin care products, provide high-precision environmental protection film packaging, and ensure the coexistence of product safety and ecological friendliness.

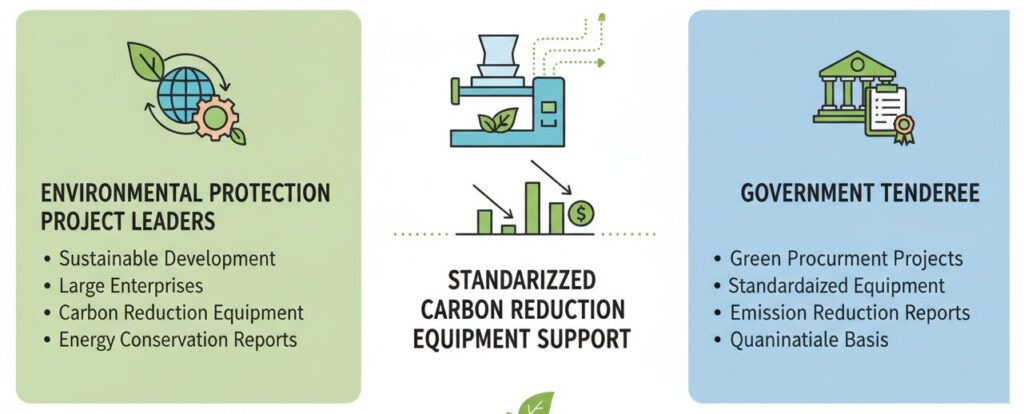

provide standardized carbon reduction equipment support for sustainable development projects within large enterprises or government green procurement projects, and provide quantitative basis for energy conservation and emission reduction reports.

Yes. Although the device is optimized for environmentally friendly materials, it is fully backward compatible with traditional plastic films such as PE, PP, BOPP, etc., and has extremely high production flexibility.

The tensile strength of the biodegradable film is generally low. We use a multi-point servo synchronous feedback system to dynamically adjust the conveying speed and tension to ensure that the material is transported under zero overload pressure, thereby preventing breakage.

Support. We can match the ultrasonic sealing module according to your needs, which can provide a more beautiful and reliable sealing effect for paper packaging or biological materials that are extremely sensitive to heat.

With modular design and touch size adjustment, skilled operators can usually switch the specifications of the entire line within 15-20 minutes, greatly reducing downtime.

Not complicated. The equipment is designed with standard parts, and the key transmission parts have an average trouble-free running time of 50,000 hours. We offer remote diagnostic systems that help troubleshoot more than 90% of operational problems online.

The equipment has built-in energy efficiency statistics software, which can display the power consumption per hour in real time. Combined with the carbon reduction coefficient of the degradable materials you use, the system can automatically calculate and generate daily/monthly carbon reduction reports to facilitate project reporting.

Our Eco Friendly Packaging Machines is specially developed for biodegradable materials and recycled paper. Through the integration of energy-saving servo system and high-precision heat sealing technology, it can reduce 30% of production energy consumption and realize 100% green packaging replacement. The supply capacity is sufficient to support batch placing orders.

Compatible with 100% degradable materials

Reduce energy consumption by more than 25%

± 0.5mm high precision servo sealing and cutting

| Parameter Items | Technical Specifications |

| Applicable Packaging Materials | PLA, PBAT, compostable film, recycled paper, water-based coated paper |

| Packaging speed | 40 – 120 packs/minute (depending on product size) |

| Bag length/width | Length: 50-400mm / Width: 50-300mm |

| Sealing and cutting accuracy | ±0.5 mm (servo drive control) |

| Rated power | 4.5 kW – 7.5 kW (Energy-efficient design) |

| Working air pressure | 0.6 – 0.8 MPa |

| control system | 10-inch touchscreen + PLC modular control |

| Noise reduction level | < 75 dB (meets industrial quiet room standards) |

| Overall material | SUS304 stainless steel (meets food-grade and environmental standards) |

this eco friendly packaging machines adopts advanced dynamic simulation design, which can maintain extremely high sealing consistency under high-speed operation. its core advantage lies in the precise temperature control (error ± 1 ℃) of temperature-sensitive biological materials, avoiding the common problems of sealing scorching or poor sealing of traditional equipment. In addition, the modular rapid mold change system equipped with the equipment shortens the switching time between different environmentally friendly materials by 50%, greatly improving the flexibility of multi-species and small batch production.

in view of the low physical strength of environmentally friendly film, the multi-stage servo tension adjustment system is adopted to solve the problem of pattern dislocation and size deviation caused by material stretching deformation during transportation.

through the integration of power feedback and frequency conversion optimization algorithm, the problem of serious power waste in intermittent production of traditional packaging lines is solved, and the energy efficiency ratio of single-piece packaging is increased by more than 20%.

the use of intelligent PID constant temperature control combined with Teflon anti-adhesive coating sealing knife solves the industry problem that heat-sensitive materials such as PLA are easy to stick to the knife, wire drawing or brittle cracking at the sealing part during sealing and cutting.

the built-in real-time tracking system of production data solves the problem that the purchaser cannot provide accurate energy consumption and waste data in the packaging process when applying for green factories or carbon neutral projects.

suitable for the pursuit of zero plastic packaging FMCG brand, can handle fruit shell paper, biofilm and other packaging, enhance the product green brand image and meet the global plastic reduction regulations.

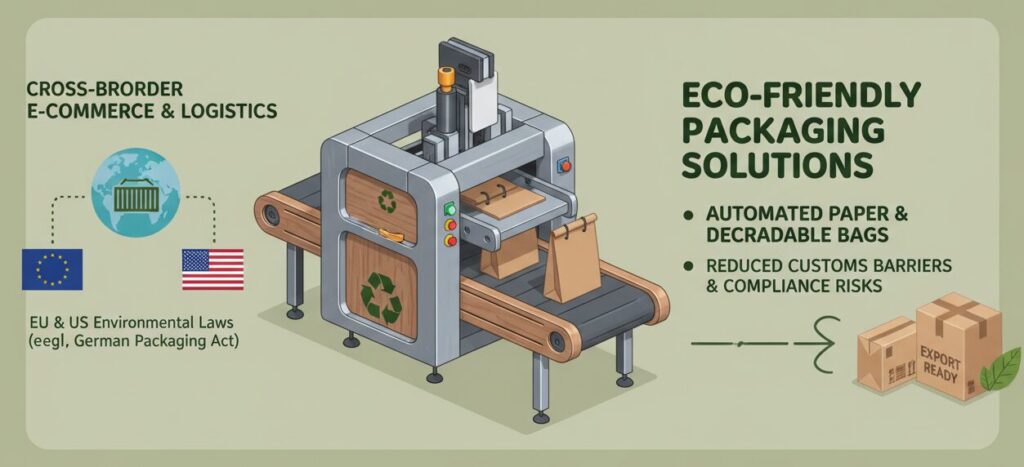

to provide automated paper bags and degradation bag packaging solutions for exporters who need to deal with stringent environmental packaging laws in Europe and the United States (such as the German packaging law) to avoid export compliance risks and reduce customs clearance barriers.

to meet the demand of aseptic production of non-toxic and recyclable packaging for medical devices or skin care products, provide high-precision environmental protection film packaging, and ensure the coexistence of product safety and ecological friendliness.

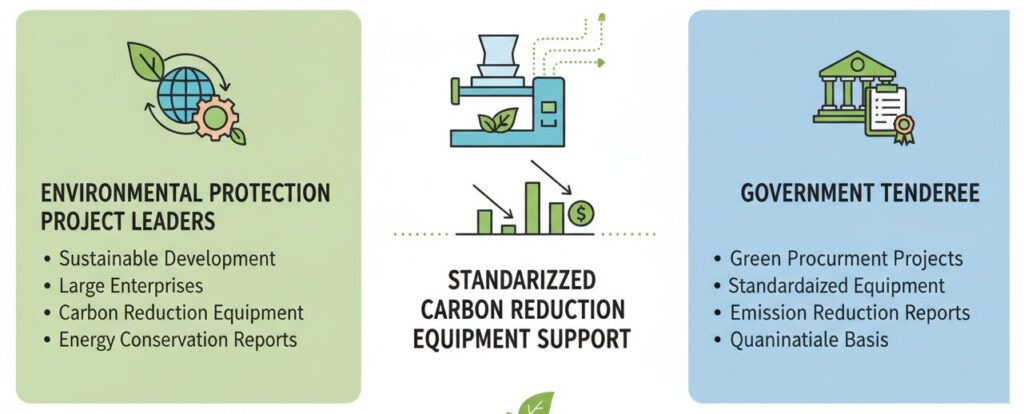

provide standardized carbon reduction equipment support for sustainable development projects within large enterprises or government green procurement projects, and provide quantitative basis for energy conservation and emission reduction reports.

A: Yes, this model adopts IP65 protection design. The stainless steel body and key motor parts have waterproof sealing covers to support the standard low-pressure water washing process of food processing plants.

A: Compatible with 5mm, 9mm and 12mm width PP packing tape. The machine is equipped with an adjustable belt guide slot, which can be switched to different specifications with simple adjustment.

A: No need. The machine has the function of automatic spitting belt. If the fault of feeding belt is detected, the broken belt will be automatically discharged and reset. Usually the recovery time is less than 10 seconds.

A: No. The tension range is electronically controllable between 10-70kg, and the minimum tension is only 10kg. It can be specially packed with lightweight cartons in combination with flexible belt (Soft Tension) mode.

A: Yes. The standard frame is 850x 600mm, we support to provide customized frames according to your product size, up to 2000mm wide.

A: The heating head is made of high-performance alloy materials. Under regular use (5000 times a day), its service life is usually more than 12-18 months.