How Does A Vacuum Packing Machine Work

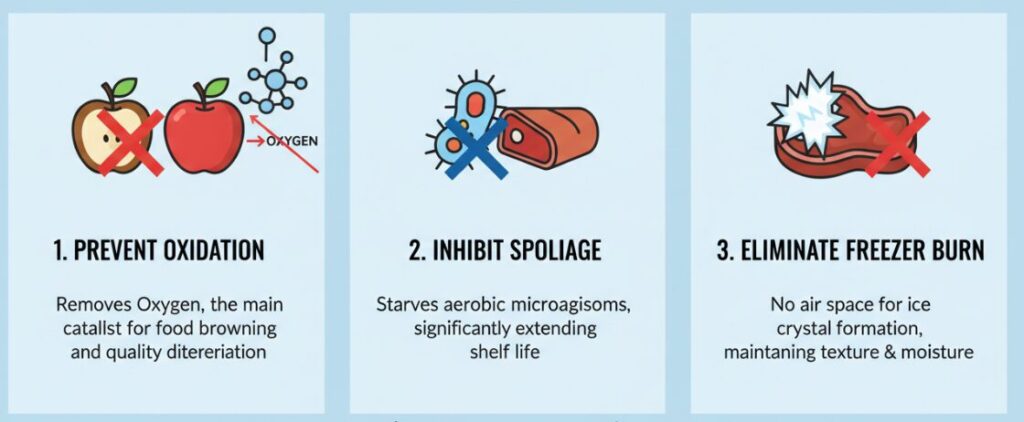

A vacuum packing machine works by using a pump to remove air (oxygen) from a plastic pouch and using heat to create a hermetic seal. While specific mechanisms vary between external suction and chamber models, the general operation involves a motor-driven pump that creates negative pressure to evacuate up to 99.9% of air, followed by a heating element that melts the bag’s material to lock in the vacuum. This preserves the product by preventing oxidation, spoilage, and freezer burn.

For components that make it work, a vacuum packing machine relies on vacuum pump, sealing bar and several control sensors to achieve a professional-grade seal. The effectiveness of a vacuum packing machine lies in its ability to alter the environment surrounding the product. It inhibit biological growth and prevent freezer burn.

Here is a video showing step-by-step process of how a vacuum packing machine works:

These are the steps summarized:

- Placement: The product is placed inside a high-barrier plastic pouch. The open end of the bag is then positioned across the machine’s seal bar (or inside the chamber cavity).

- Extraction (Vacuuming):Once the lid is closed or the cycle creates a trigger, the vacuum pump activates. It sucks the air out of the bag (or the entire chamber), creating a vacuum environment around the product.

- Sealing: Immediately after the air is removed, the heating element (seal bar) presses against the bag’s open end, melting the plastic layers together to form an airtight seal.

- Release: The machine releases the pressure, the lid opens, and the vacuum-packed product is ready for storage.

Motor Driven Pump And “Negative Pressure”

The “heart” of this machine is undoubtedly the motor-driven vacuum pump. Many people have a misunderstanding about vacuum packaging, thinking that the machine is “squeezing” the bag. In fact, to understand this machine, you have to understand negative pressure first. When the pumping phase begins, the pump is not physically squeezing the bag, but is actively removing atmospheric particles, reducing the pressure within the bag (or chamber) to a level well below the external atmospheric pressure.

- Manufacturing Gap: By expelling up to 99.9% of the air, the machine creates a huge pressure difference-the air pressure outside the bag is significantly higher than inside the bag.

- Collapse And Fit: It is this physical principle that forces the flexible high-barrier plastic bag to collapse inward and tightly fit on the surface of the product. This tight fit is entirely due to the vacuum environment in which the pump is made, rather than mechanical compression.

Vacuum Packing Machine Working Steps

Although the above overview can give you a general idea, if you want to use the machine well and get the best preservation effect, we have to dig out the details.

Step1: Placement

It all starts with placement. You must use a high-barrier plastic pouch. These bags are specially engineered to withstand the pull of the vacuum and the heat of the seal without breaking. Ordinary fresh-keeping bags will not work here.

Positioning Skills

It is very important to correctly place the bag mouth on the sealing strip. If the bag mouth is wrinkled or not laid flat on the strip, the machine cannot form the “airtight seal” required to maintain the “vacuum”. Many air leakage problems are caused by not setting up here.

Step2: Pumping

Entering the pumping stage, the machine enters the full power operation state. Depending on whether it is an external extraction or chamber machine, the airflow path is slightly different, but the same way:

- Exterior Models: This type of machine usually needs to be matched with a bag with lines, and the air is “sucked” directly through the tiny channels in the bag texture.

- Chamber Models: It is to pump the air out of the entire chamber. This balances the pressure inside and outside the bag, allows for more vigorous pumping, and-critically-does not crush fragile foods before sealing.

Step3: Sealing

Once the sensor detects that the preset vacuum level (negative pressure value) is reached, the machine will seamlessly switch to the sealing mode.

- Heating Element: A heating element (usually a resistance wire) is installed inside the sealing strip.

- Melting Layer: The machine simultaneously applies pressure and heat to the mouth of the bag. It’s not just sticking together, but letting the inner layers of the plastic melt and fuse at the molecular level. This is the “airtight seal” I mentioned at the beginning, ensuring that once the vacuum pump is stopped, there is no possibility of air flowing back into the bag.

Step4: Release

The final step is release. After the sealing is completed, the machine stops the operation of the pump.

- Air Backflow: A valve opens to allow air to quickly rush back into the chamber (or move away from the suction nozzle).

- Locking Vacuum: Since the bag has been sealed, the atmospheric pressure from the outside will instantly press the bag on the food. This is the moment when the vacuum state is “locked”.

Key Components That Determine Machine Performance

A professional-grade vacuum machine can do a good job, mainly depends on these core components:

- Vacuum Pump: The industry calls it the “heart” of the machine. Its exhaust rate directly determines the pumping efficiency and the final vacuum depth.

- Sealing Bar: Rely on resistance wire to generate heat. Good sealing bar heat distribution is very uniform, there will be no air leakage breakpoint.

- Control Sensor: Now the intelligent machine with this. They can monitor the pressure in real time to ensure that every time the air is pumped, it reaches the optimal level and then triggers the seal, rather than patting the head and feeling it.

Why Is Vacuum Packaging So Effective For Preservation

From the perspective of packaging engineering, the essence of the vacuum machine is to change the microenvironment around the product.

Inhibition Of Biological Growth

Most of the culprits that cause food spoilage-aerobic bacteria and molds-cannot live without oxygen. By pumping the oxygen away, the microbial reproduction process is pressed the pause button, and the rate of decay naturally slows down.

Prevent Freezer Burn

Vacuum packaging is also a mean to deal with freezing burns. The kind of cold and frosty situation is actually due to air entering the package. The vacuum machine eliminates all air pockets and keeps the food surface close to the package, protecting the meat and taste. To be honest, even if you put it in the cold storage for a few months, the taste when you take it out is not much different from when you just put it in.

Author: Liam Miller

“I am a packaging machinery specialist with over a decade of experience in food preservation technology. My work focuses on deconstructing complex sealing mechanics—from vacuum pumps to heat bars—to help businesses optimize their packaging processes for maximum freshness and durability.”

Soonqian

Soonqian