Blister Packing Machine Working Principle

In general, the Blister Packing Machine Working Principle involves a comprehensive process of heating a plastic film, forming cavities, filling them with products, and sealing them with a backing material. In essence, the machine transforms raw packaging materials (like PVC and aluminum foil) into finished blister packs through a continuous, automated sequence designed to ensure product protection and visibility.

This video shows you some steps and dive into the engineering details you need to know:

The working process can be broken down into 5 key steps:

- Heating & Unwinding: A plastic film sheet is unrolled and passed through a pre-heating station specifically designed to make the material pliable and ready for molding.

- Blister Forming: The softened film is molded into precise cavities using either compressed air or mechanical traction, creating the “pockets” for the product.

- Material Filling: Products (such as tablets, capsules, or small goods) are automatically deposited into the formed blisters by a dedicated feeder.

- Heat Sealing: A lidding material (typically aluminum foil) is applied over the filled blisters. The machine uses heat and pressure to permanently bond the lid to the blister film, creating a hermetic seal.

- Punching & Output: The sealed web moves to a cutting station where batch numbers are often embossed, and individual packs are punched out from the continuous strip for final collection.

Different Types Of Blister Packaging Machine Have Different Working Principles

1. Roll Blister Packaging Machine

Simply put, it is to bake the formed film soft through a heating device, and then use the vacuum negative pressure on the forming roller to directly “suck” the film into a blister shape. Then the packing device puts the things in, and then runs to a roller-type heat sealing link. Under the appropriate temperature and pressure, the adhesive-coated covering film is sealed on the surface of the blister.

Finally, the machine will automatically mark the production batch number, press out the dotted line, and then cut it into the finished product specifications we want by the blanking device. The biggest advantage of this roller structure is strong continuity, but the thickness uniformity of the film material is actually quite high. Once heated unevenly, the blister is easily deformed.

2. Flat Blister Packaging Machine

The routine of the Flat blister packaging machine is a little different. It first uses a flat heating plate to soften the film, and then uses compressed air to “blow” into the forming mold instead of suction to blow out the blister. After the material is filled, it will be sent to the plate sealing device. Under specified warm pressing conditions, the cover film and the flat mold are pressed tightly together to complete the seal.

The next steps are familiar to everyone: typing the batch number, pressing the tear line, and finally punching out the finished product. I think that the flat plate type is often more stable than the roller type in molding accuracy, especially when dealing with deep drawing or packaging with complicated shapes, the blow molding effect is usually more symmetrical than vacuum blister.

3. Roll Plate Blister Packaging Machine

As for this kind of Roll plate blister packaging machine, it is a “hybrid”, which evolved on the basis of the previous two machines. It adopts the strategy of “learning from each other’s strengths”: when forming, it uses flat-type positive pressure blow molding (that is, flat-type forming method); However, in the sealing process, it was replaced by roller sealing.

Its basic working logic is not bad from the two big differences mentioned earlier. The manufacturer developed this model, in fact, is trying to find a balance between molding quality and sealing speed. If you want both the flatness of flat molding and the high efficiency of roller sealing, you must be right to choose this machine.

Blister Packaging Machine Work Flow

Step 1: Heating And Unwinding Station

The starting point of the working principle is the unwinding station, from which the formed film (usually PVC, PVDC or cold-punched aluminum Alu-Alu) is fed into the machine. Here is an easy to ignore but critical point-tension control. If the tension is not adjusted properly, the sheet is either stretched and deformed, or it has already wrinkled before entering the heating zone. After the film is released, it is followed by a preheating station. This is arguably the most thermal phase of the entire working principle, as the thermoplastic material must reach its specific “glass transition temperature” .

- Temperature control: The upper and lower heating plates will heat the sheet evenly. If the temperature is too low, the plastic will crack during molding; if the temperature is too high, the wall thickness will become too thin or even rupture after stretching.

- Flexibility: Our goal is to make the hard plastic sheet soft enough to be shaped, but to retain enough toughness to hold the shape after cooling.

Step 2: Blister Forming Mechanism

To this step, it really touched the core of the blister machine. Once the sheet heat softens, it must immediately enter the forming station. Depending on the model (flat or drum), we usually use two engineering methods to create “bubble eyes”:

- Compressed air molding : the use of high-pressure air to soften the film into the mold cavity. This method is standard standard PVC blister, the advantage is more uniform wall thickness.

- Mechanical traction: If you want to make a deep bubble eye, or the material is difficult to make, it is not enough to rely solely on air blowing. At this time, a mechanical punch (Plug) is needed to press the film hard into the mold, and then cooperate with air pressure to assist in forming.

This step turns the flat sheet into rows of empty pockets waiting to be filled. The accuracy of the mold directly determines whether the geometry of the final drug plate is regular.

Step 3: Automatic Material Filling

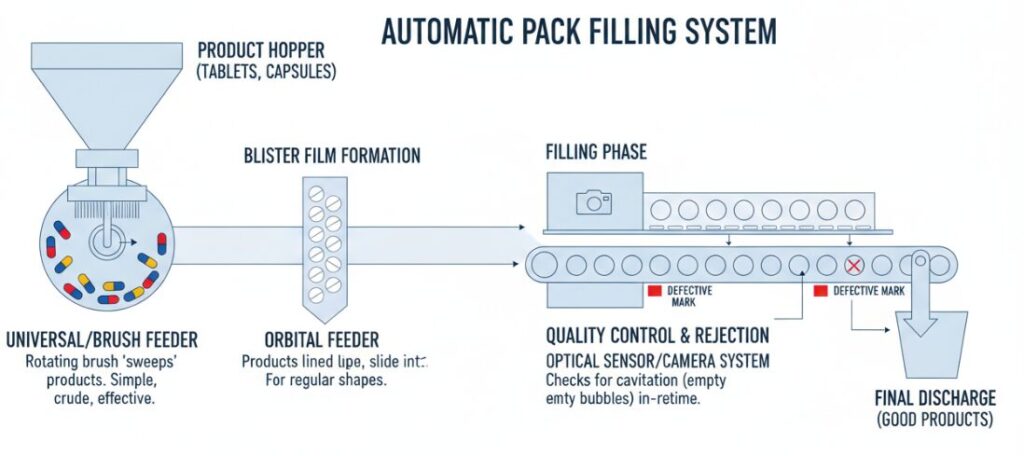

During the filling phase, synchronicity is the biggest engineering challenge. As the formed coil moves forward, the automatic feeder must accurately put the product (tablet, capsule or small ampoule) into the bubble eye during high-speed operation. According to the material characteristics, we usually choose different feeder:

- Universal/Brush Feeder: Use a rotating brush to “sweep” the product in the hopper into the bubble eye, simple, crude but effective.

- Orbital feeder: products are lined up in the track and slide directly into the blister, which is suitable for products with regular shapes.

Today’s high-end models usually integrate optical sensors or camera systems at this stage. This stuff is very necessary to check whether each bubble is filled in in real time. If cavitation is found, the logic system of the machine will mark this section and automatically reject it when the final discharge is made.

Step 4: Heat Sealing Station

After loading the material, it entered the sealing link. The working principle here is that the cover material (usually aluminum foil coated with heat seal paint) is pressed together with the formed PVC coil.

- Ailleted sealing: The heated sealing roller or sealing plate will exert great pressure on the coil. The heat activates the lacquer on the aluminum foil, causing it to fuse with the plastic sheet.

- Texture pressing: The grid-like “knurling” pattern on our common medicine board is pressed out here. This is not only for good looks, from a physical point of view, reticulation can maximize the contact surface area, thereby forming a closer bond, ensuring air tightness, and keeping moisture, oxygen and light out.

Step 5: Punching, Embossing & Output

This is the final sprint stage of the blister machine workflow, to turn the continuous sealing coil into an independent finished product plate.

- Stamping: Before cutting, there is usually a station responsible for stamping key data such as batch number, production date and expiration date on the edge of the package.

- Stepping Index (Web Indexing): This is usually controlled by a servo motor or stepping mechanism, which pulls the coil forward with extreme precision to ensure that the sealed blister can be aligned with the die. If the position is slightly off, the whole board will be useless.

- Punching: The die cutter falls down and punches out the blister card of the finished product.

- Scrap collection: The remaining scrap (skeleton-like grid) is rolled up or directly crushed for recycling.

Finally, the finished tablet is discharged through a chute or conveyor belt. Usually there is also a checkweigher or reject station here, where the non-conforming products (such as vacuoles) previously marked by the sensor are kicked out to ensure that only perfect products flow to the back-end packaging line.

Author: James Wilson

“Hi, I’m the Senior Engineer. With over a decade of hands-on experience in pharmaceutical packaging technology, I specialize in optimizing blister packing lines. I write to help manufacturers understand the complex mechanics behind efficient packaging machinery.”

Soonqian

Soonqian